In an ideal world, all holes in etched parts would exactly the right size. However the limitations of the manufacturing process mean that the world isn't ideal, so a good designer will arrange for them to be slightly undersize.

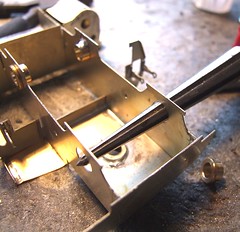

On the Garratt the holes for the axle bearing are about 6mm in diameter. The bearings are 6.6mm so a light touch with the tapered reamer ensures a snug fit.

Years of experience have taught me to be very careful doing this. It's very easy to take out so much metal that the bearing slops around - fine if you are using a jig to line everything up but hopeless otherwise.

It's also one of those jobs where the right tool makes a big difference. I'm using a Draper tapered reamer and it's a whole lot easier than trying to do the same job with a needle file. The later is likely to result in an oval hole whereas I know that what I end up with is to all intents and purposes, round. If you go reamer shopping unless you are a 7mm scale modeller, who can get away with the 7 quid bigger reamers, reckon on spending 12 to 14 pounds on something suitable for the smaller 4mm scale holes you'll be dealing with. The tool pictured will only just go in the smaller holes.

If this sounds a lot of money then console yourself with the fact that the tool will last for years and be useful wherever you find a hole that needs opening out.

No comments:

Post a Comment