The armoured locomotive is made up of large resin castings. A dry-build (posh term for putting the bits together without glue so you can take them apart again) revealed that the boiler unit sat on the footplate with a gap under it at each end.

The armoured locomotive is made up of large resin castings. A dry-build (posh term for putting the bits together without glue so you can take them apart again) revealed that the boiler unit sat on the footplate with a gap under it at each end. Checking the base with a ruler confirmed that the boiler was the problem. Ideally I wanted to take out about 1/4 of a mm from the centre and leave the ends alone.

What I didn't want to do was make the problem worse by filing the bottom flat but not parallel to the top. Dragging it back and forth along a file sat on the workbench seemed to do the job. I kept turning the part over to see where the scratches were and make sure they weren't at the ends where I wanted to keep the material.

Another problem was that to my eye, the unit was very, very slightly too long. It's a snug fit up against the front of the cab so it's another spot where filing away and producing a wonky part is going to show, or at least take some filer work to hide the bodge.

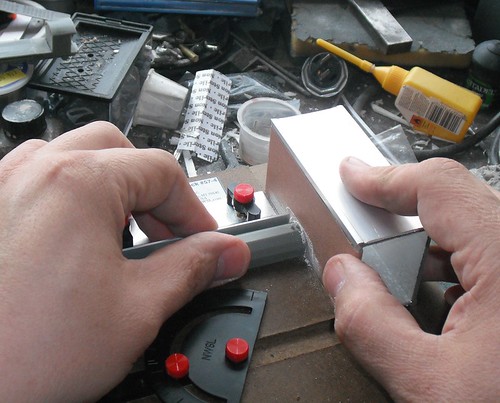

Fortunately, I have just the tool. A pricey True Sander from North West Shortline, bought from EDM Models in a fit of enthusiasm. Basically, a masonite base with an aluminium block that runs back and forth with some abrasive paper wrapped around it. The important point is that the set-up keeps the sandpaper at 90 degrees to whatever is being sanded.

I took that picture by clamping my cheap compact camera between chin and throat. Not sure the proper photographers work like that but it went surprisingly well. And yes, my modelling bench is a mess. That's how I roll.

After this, the parts went together well with superglue and the loco looks nice. Sadly the shadow means you can't see the well detailed backhead, but the pipes and controls are all in there.

No comments:

Post a Comment