A daily updated blog typed by someone with painty hands, oil under his fingernails and the smell of solder in his nostrils who likes making all sort of models and miniatures. And fixing things.

Wednesday, December 17, 2014

Railcar chassis

John asks: Have you ever thought of making a GWR railmotor? This is something that I I always wanted. I'm not looking for a lot of detail just an overall look and was wondering whether something could be made with the Hornby auto coach.

This isn't the first time I've been asked about railcars recently.

To start with John's question. Possibly BUT the body isn't the difficult part of such a conversion. Finding a suitable chassis with all the waggly valve gear bits is pretty much impossible. Maybe there is something from a continental range that could form a basis but it's going to be a lot of work.

Far better, if I'm honest, to await the RTR version from Kernow Model Centre. For £150 and a bit of a wait, I don't think you'll beat it.

However, this isn't a blog where I sit and wait for someone in China to be told by the bloke who used to run Banbury model railway exhibition what to do. No, I still have a Nu Cast whitemetal kit to build.

When I left the model, I'd put the powered end chassis together and was about to fit the mechanical bits. Easy, or so you might think.

Well, persuading the motor to fit in the casting that appeared to be the mount took me over an hour. Lots of filing and scraping at the whitemetal to make the distance between the sides wide enough to slip the DS10 in place.

Eventually, there was success. With a couple of plasticard wedges, the motor turned under power and didn't rattle the sides.

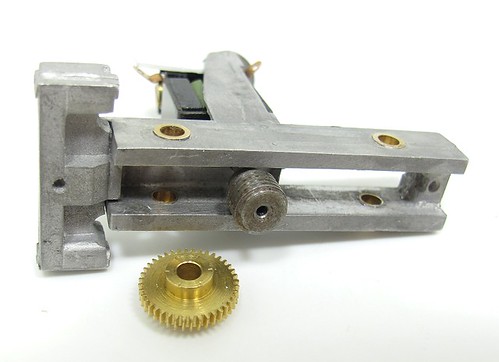

Then I had a look at the gears. And there was a problem. Oh, yes, a good 'un.

The worm gears is too fat for the chassis and even if I fix that, it's nowhere near the gear on the axle.

Re-reading the instructions, I spot a tiny note on the drawing showing the motor doesn't fit where I thought. It should be on the back of the casting. Arghhhh!

However, this isn't the solution you might hope for there are some issues.

First, it appears to be held in place with willpower and possibly fairy dust. Certainly no screw attachment points or castings are shown to do the job and nor are they evident on the model.

Second, the gears are still in different time zones and the worm isn't going to fit any better between the frames.

I'm sure there is a fix for this, probably a different motor/gearbox combo (no I won't use a SPUD at the other end, I want the waggly bits powered) but I need to know how much space is available. Therefore the next job is to build the body and see how all this lot hangs in there.

Labels:

GWR Railcar,

model railway

Subscribe to:

Post Comments (Atom)

2 comments:

The old white metal casters' problem of shrinkage, assuming the master worked in the first place. Don't blame the patternmaker. I've been making brass masters since 1971 and I have never yet found a caster who could give me a reliable shrinkage figure. I've heard everything from "Nothing much" to 8% cross sectional, 5% linear. And resin's no better. Sometimes it does, sometimes it don't. Linear can be almost negligible, whilst cross sectional can astonish you! The answer, is epoxy, which few do, but shrinkage is not a problem.

Persevere as it's only a chunk of w/m, to which corrections can be either wrought or attached. No sweat!

'tis true. Whitemetal solder is wonderful stuff for replacing anything removed in error.

Post a Comment