A daily updated blog typed by someone with painty hands, oil under his fingernails and the smell of solder in his nostrils who likes making all sort of models and miniatures. And fixing things.

Tuesday, May 20, 2014

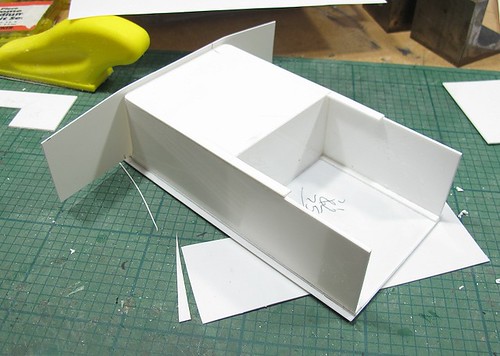

Maritime adventures with plasticard

I thought this would be easy. The top of the Bantam tugboat looked oh so square and simple. Industrial design where all corners are cut to produce the least complex design for ease of building.

Then I took a proper look at the photos.

At the front, the superstructure slopes backward ever so slightly - enough to be noticeable so I can't ignore it. The front corners are curved too.

After a bit of head scratching, I made a top and bottom for the box out of thick plasticard. The top and bottom are slightly different sized to provide the front slope. This lot sits in a base 2mm wider all round to give me the visible flange at the deck line. Under here we have a piece the same size as the hole in the deck.

Some thin (you'll notice I don't know what the thickness is - I'm pulling random bits out of the plasticard bag) sheet was cut and wrapped around the front to give the slope. Had I not fitted this to a base, I wouldn't have had to indulge in fiddly fitting of sloped sides. I could have allowed an overlap top and bottom and then trimmed back.

At least the work area smelled nice after this. Using Limonene to laminate the sheets results in a pleasant citrus smell. There's not many modelling tasks this achieve this.

Labels:

Bantam Tug,

model boat

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment