One thing I hate when spraying paint is getting bits of dust stuck to the surface. This always seems to happen to me when because I do my airbrushing in the garage. While the air is reasonably free of dust, a few specks still seem to float around.

I might have imagined it but I’m sure I read somewhere those professionals use cellulose thinners, not enamel, when airbrushing. The theory is that the more volatile thinner evaporates faster drying the paint. The faster the paint dries the less chance there is of getting surface contamination (listen to me, “surface contamination” – meaning cr*p in the paint) leading to a better finish.

Now this really matters with gloss paint which takes about a week to go off (for me anyway) but I don’t have anything needing gloss painting so I have had to try the technique with matt black. To be honest a shaved monkey could spray this colour successfully but I had a go anyway.

Result, well it might have dried a little quicker and there certainly isn’t any dust in the finish, I have a feeling that the paint flowed better out of the airbrush as well but I didn’t run any through enamel thinned paint to check. I’ll try this again with the satin varnish later to see if this works.

A daily updated blog typed by someone with painty hands, oil under his fingernails and the smell of solder in his nostrils who likes making all sort of models and miniatures. And fixing things.

Saturday, June 30, 2007

Cellulose thinners

Wednesday, June 27, 2007

Jigging

The Barclay gave me the opportunity to rest out a new modelling gadget that I inherited. It’s a Mastermodels jig. In theory this is going to guarantee a nice square chassis which in turn should mean that the locomotive will run properly first time.

You are supposed to the set the axles by putting the ends through the holes in the con rods. This sets the wheelbase. All the jigs are locked in using Allen bolts. The bits of chassis then slide onto the axles and soldered together. Accuracy guaranteed.

Unfortunately the axles ends are 1.5mm wide and Romford cranks are 1mm. I’ll need to see if I can order another set with the right ends. As it was I used one side of the chassis hoping that the squareness of the jig will do the job.

Soldering the bits together was fiddly as I was trying to hold all the bits at once. I managed it though, and once I assembled the wheels and rods things ran nicely.

So far so good. Maybe this will cure all those sticky chassis anxieties for the future.

You are supposed to the set the axles by putting the ends through the holes in the con rods. This sets the wheelbase. All the jigs are locked in using Allen bolts. The bits of chassis then slide onto the axles and soldered together. Accuracy guaranteed.

Unfortunately the axles ends are 1.5mm wide and Romford cranks are 1mm. I’ll need to see if I can order another set with the right ends. As it was I used one side of the chassis hoping that the squareness of the jig will do the job.

Soldering the bits together was fiddly as I was trying to hold all the bits at once. I managed it though, and once I assembled the wheels and rods things ran nicely.

So far so good. Maybe this will cure all those sticky chassis anxieties for the future.

Monday, June 25, 2007

Deja-vu

I’m doing another Barclay. I think this will be the fifth one I’ve built from the Mercian kit. People keep asking me.

Of course the good thing is that as I’ve built the kit before I cab crack on quickly. What you see is the result of an Inspector Morse (DVD, about 1.75 hours) and the film 28 Days later (Channel 4 so say a couple of hours) plus an extra hour or so.

The trickiest job is the handles on the bonnet. A couple of locos ago I figured this out. You don’t cut the handles to length until they are soldered in. Basically the trick is to bend the end of the wire, solder it in position and then cut the remains to length. I use an old business card as a spacer so they are all the same distance from the side.

OK so this is the 80% that takes 20% of the time but there is detail so I don’t think I am very far away from finishing. Mind you I still have to make it work and as this model is in HO (3.5mm scale) that isn’t as easy as the OO version. The cab steps get in the way of the rod as I recall…

Of course the good thing is that as I’ve built the kit before I cab crack on quickly. What you see is the result of an Inspector Morse (DVD, about 1.75 hours) and the film 28 Days later (Channel 4 so say a couple of hours) plus an extra hour or so.

The trickiest job is the handles on the bonnet. A couple of locos ago I figured this out. You don’t cut the handles to length until they are soldered in. Basically the trick is to bend the end of the wire, solder it in position and then cut the remains to length. I use an old business card as a spacer so they are all the same distance from the side.

OK so this is the 80% that takes 20% of the time but there is detail so I don’t think I am very far away from finishing. Mind you I still have to make it work and as this model is in HO (3.5mm scale) that isn’t as easy as the OO version. The cab steps get in the way of the rod as I recall…

Saturday, June 23, 2007

Expensive kits

This morning involved a quick trip to Howes to get the mechanical bits for a boat my Dad is building. It’s an interesting shop with an excellent model railway section in the front, a room of plastic kits and then a large radio control section at the back.

The kits in the picture were two I bought because the plastic kit room has a 25% off sale on. Because it’s being closed down to be replaced with yet more RTR tanks, planes, cars and boats. Apparently plastic kits don’t sell.

This is terrible news. Plastic kits are one of the ways people get into model making. Most people remember sticking Airfix Spitfires together. From this humble start they get the bug for making things and move on to more specialised areas.

If I think about the town where I live, should I want to buy a plastic kit my only option is Woolworths – and even there I’ll have a very tiny selection. Now Leamington is notoriously rubbish for shopping but other towns aren’t much better served. The traditional toyshop has gone. The model shop is a rare find.

Now I understand the retailers problem. Millions of different plastic kits are produced and you can’t afford to stock even a small selection of them. I bought a Russian ice-breaker. Why does anyone even contemplate tooling up such a kit ? Then why does a shop tie up money in sitting it on the shelf to await someone buying it just because it’s in the sale.

“You can still buy kits on the web”, I hear you cry. True but that’s only any good when you are an established modeller. Where does the impulse buy, or even more importantly the “pester power” buy come from if you don’t see the seductive kit box sat on the shelf ?

These may have been cheap kits, but in the long run they and their kin might be very expensive for the hobby.

The kits in the picture were two I bought because the plastic kit room has a 25% off sale on. Because it’s being closed down to be replaced with yet more RTR tanks, planes, cars and boats. Apparently plastic kits don’t sell.

This is terrible news. Plastic kits are one of the ways people get into model making. Most people remember sticking Airfix Spitfires together. From this humble start they get the bug for making things and move on to more specialised areas.

If I think about the town where I live, should I want to buy a plastic kit my only option is Woolworths – and even there I’ll have a very tiny selection. Now Leamington is notoriously rubbish for shopping but other towns aren’t much better served. The traditional toyshop has gone. The model shop is a rare find.

Now I understand the retailers problem. Millions of different plastic kits are produced and you can’t afford to stock even a small selection of them. I bought a Russian ice-breaker. Why does anyone even contemplate tooling up such a kit ? Then why does a shop tie up money in sitting it on the shelf to await someone buying it just because it’s in the sale.

“You can still buy kits on the web”, I hear you cry. True but that’s only any good when you are an established modeller. Where does the impulse buy, or even more importantly the “pester power” buy come from if you don’t see the seductive kit box sat on the shelf ?

These may have been cheap kits, but in the long run they and their kin might be very expensive for the hobby.

Friday, June 22, 2007

Working up top

The reason the inside of the wheelhouse has been detailed is because the roof is off. And the reason the roof is off is because I needed to detail it.

Now this wouldn’t be necessary if I hadn’t planned on putting working lights up there. In a boat this size it seems a shame not to do this though. I like sailing Pigeon Pie at dusk with her lights on and so I want the same option for Tomsk. Besides if the boat sinks again, at least I stand a chance of seeing it in the water !

The navigation lights are brass and the mast light plastic. I think they are both from Robbie but have thrown the packaging away. If I’m wrong it doesn’t matter too much as there are plenty of people who do these things.

Putting the wires up the mast took some serious fiddling – they are very thin and prefer to roll themselves up in the tube rather than be pushed through. I reckon that little job took half an hour and nearly resulted in the roof being flung across the room !

The “grain of wheat” bulbs in the lights are 3V, and I didn’t spot this until I had installed everything. Since the battery gives 8V I’ll need a dropper resistor to stop them frying. My physics was never good enough for this so I’ll use the same ones I use for dropping 12v down to power LED’s and hope that there is enough juice to light the bulbs.

The radar done is scratchbuilt and on the small side. I used the largest plastic tube from the local model shop and it’s still only ¾’s the size it should be. I’ll have to keep an eye out for a commercial replacement. It’s not worth buying big enough pipe as I only want about 10mm and will need to buy 6 feet !

Now this wouldn’t be necessary if I hadn’t planned on putting working lights up there. In a boat this size it seems a shame not to do this though. I like sailing Pigeon Pie at dusk with her lights on and so I want the same option for Tomsk. Besides if the boat sinks again, at least I stand a chance of seeing it in the water !

The navigation lights are brass and the mast light plastic. I think they are both from Robbie but have thrown the packaging away. If I’m wrong it doesn’t matter too much as there are plenty of people who do these things.

Putting the wires up the mast took some serious fiddling – they are very thin and prefer to roll themselves up in the tube rather than be pushed through. I reckon that little job took half an hour and nearly resulted in the roof being flung across the room !

The “grain of wheat” bulbs in the lights are 3V, and I didn’t spot this until I had installed everything. Since the battery gives 8V I’ll need a dropper resistor to stop them frying. My physics was never good enough for this so I’ll use the same ones I use for dropping 12v down to power LED’s and hope that there is enough juice to light the bulbs.

The radar done is scratchbuilt and on the small side. I used the largest plastic tube from the local model shop and it’s still only ¾’s the size it should be. I’ll have to keep an eye out for a commercial replacement. It’s not worth buying big enough pipe as I only want about 10mm and will need to buy 6 feet !

Thursday, June 21, 2007

Noodling with plastic

Here’s a nice pleasant little job – detailing the wheelhouse of my tugboat.

No plans, just a bit of creative work with some offcuts of plasticard, tube and assorted bits of kit leftovers.

The main thing was to put some controls in front of the skipper. A small panel with some dials and a radar display was quickly made from plastic. I even put some switches in using thin plastic rod. Better modellers than me would actually work out what all this stuff is supposed to do. A quick look through some magazines didn’t show any wheelhouse interiors of similar boats so I had to guess.

A radio, mug and thermos flask give the model a bit of life. The scrapbox supplied a Slaters 4mm scale suitcase which makes a reasonable giant sized lunchbox.

All that’s left is a newspaper. Ideally I suppose this out to be the Sun but my skipper is likely to read a Guardian like me.

No plans, just a bit of creative work with some offcuts of plasticard, tube and assorted bits of kit leftovers.

The main thing was to put some controls in front of the skipper. A small panel with some dials and a radar display was quickly made from plastic. I even put some switches in using thin plastic rod. Better modellers than me would actually work out what all this stuff is supposed to do. A quick look through some magazines didn’t show any wheelhouse interiors of similar boats so I had to guess.

A radio, mug and thermos flask give the model a bit of life. The scrapbox supplied a Slaters 4mm scale suitcase which makes a reasonable giant sized lunchbox.

All that’s left is a newspaper. Ideally I suppose this out to be the Sun but my skipper is likely to read a Guardian like me.

Wednesday, June 20, 2007

Meltdown

I hadn’t spotted this until yesterday. It looks like when I was fighting with the G1 locomotive I must have left the little blowtorch pointing in the wrong direction while fiddling with something else.

At least nothing caught fire…

At least nothing caught fire…

Monday, June 18, 2007

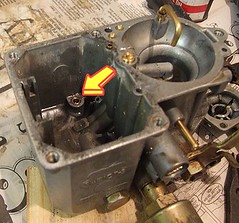

Crud killed my bus

My carburettor is dead.

After a couple of weeks squirting cleaner through it I’ve had to accept defeat. It’s nearly right but not nearly enough. When I press the accelerator I want the engine to rev – not burble and die. I think the problem was due to muck in the accelerator pump but despite drilling out the outlet and making sure the check ball was free, the problem’s still there.

The cause is the stuff in the photo. A weird silt that built up in the bottom of the carb and all the passages. It’s obviously the residue of the muck that was in the petrol tank. Normally it would have flushed through but with the van off the road it solidified. It also ate its way into the metal with several stains on the body and ancillaries. The stuff in the pump fitting took some serious drilling to remove.

I obviously haven’t got all of it though. Since carb cleaner – a pretty vicious substance – won’t shift it I have to choose between spending lots more time cleaning or take the hit to my wallet and buy a new one. Of course I can’t guarantee this will fix the problem but the first cleaning improved the power a lot so I’m hoping a new carb will get my van on the road properly.

Fingers crossed.

After a couple of weeks squirting cleaner through it I’ve had to accept defeat. It’s nearly right but not nearly enough. When I press the accelerator I want the engine to rev – not burble and die. I think the problem was due to muck in the accelerator pump but despite drilling out the outlet and making sure the check ball was free, the problem’s still there.

The cause is the stuff in the photo. A weird silt that built up in the bottom of the carb and all the passages. It’s obviously the residue of the muck that was in the petrol tank. Normally it would have flushed through but with the van off the road it solidified. It also ate its way into the metal with several stains on the body and ancillaries. The stuff in the pump fitting took some serious drilling to remove.

I obviously haven’t got all of it though. Since carb cleaner – a pretty vicious substance – won’t shift it I have to choose between spending lots more time cleaning or take the hit to my wallet and buy a new one. Of course I can’t guarantee this will fix the problem but the first cleaning improved the power a lot so I’m hoping a new carb will get my van on the road properly.

Fingers crossed.

Sunday, June 17, 2007

Winner !

It was the DOGA AGT (Annual Get-together, we aren't dull enough for an AGM) yesterday and for a change I actually won class in the modelling competition !

Samuel won the Kitbuilt & Scratchbuilt class beating several large locomotives.

Go to: http://www.doubleogauge.com/AGMComp/competition2007.htm to take a look.

Friday, June 15, 2007

Slingshot Mods part 1

In theory all the water should stay on the outside of any model boat. Water inside means you have a submarine – fine if that’s what you built but otherwise not something that leads to happiness. I suppose this is one area where models are just like the real thing !

However if you are as rubbish at racing as I am and your boat spends time upside down, water in the works is a certainty.

Slingshots seem reasonably resilient to internal wetness but eventually the speed controls die from it. As bought this is attached to the back of the motor. Since I wanted to waterproof it all three wires were carefully desoldered and extended. Then the circuit board has been wrapped in a plastic bag.

I have tested this and the speed control is still working. The motor wasn’t happy but at least the electronic survive and the motor is much simpler to dry out.

However if you are as rubbish at racing as I am and your boat spends time upside down, water in the works is a certainty.

Slingshots seem reasonably resilient to internal wetness but eventually the speed controls die from it. As bought this is attached to the back of the motor. Since I wanted to waterproof it all three wires were carefully desoldered and extended. Then the circuit board has been wrapped in a plastic bag.

I have tested this and the speed control is still working. The motor wasn’t happy but at least the electronic survive and the motor is much simpler to dry out.

Thursday, June 14, 2007

Great Inventions No. 64532

Quick drying varnish that you can clean off the brush with ordinary water.

Without it I wouldn’t have been able to slap two coats on Tomsk’s transport box on a warm afternoon. The results look pretty good too. I gave the wood a quick sand between the coats and ended up with a nice smooth finish.

According to the side of the can the results will be reasonably waterproof too. Pretty important when I plan to stick a wet boat back inside sometimes !

I confess that I don’t understand how anything that can be washed off the brush with soapy water can survive getting wet but then I failed my A-Level chemistry for being stupid so perhaps I’m not best placed to work it out.

What I do know is that along with the rest of the world, I hate washing out paintbrushes in turps. It’s a messy smelly job that often leads to brushes being abandoned in jam jars of stinky cleaner. We might not have domestic robots yet but easy clean varnish is a pretty good alternative.

Without it I wouldn’t have been able to slap two coats on Tomsk’s transport box on a warm afternoon. The results look pretty good too. I gave the wood a quick sand between the coats and ended up with a nice smooth finish.

According to the side of the can the results will be reasonably waterproof too. Pretty important when I plan to stick a wet boat back inside sometimes !

I confess that I don’t understand how anything that can be washed off the brush with soapy water can survive getting wet but then I failed my A-Level chemistry for being stupid so perhaps I’m not best placed to work it out.

What I do know is that along with the rest of the world, I hate washing out paintbrushes in turps. It’s a messy smelly job that often leads to brushes being abandoned in jam jars of stinky cleaner. We might not have domestic robots yet but easy clean varnish is a pretty good alternative.

Wednesday, June 13, 2007

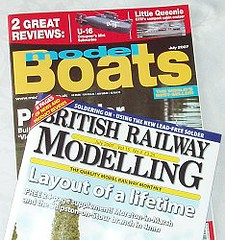

Double Whammy

This is a good month for my writing efforts – two magazines came through the door on Monday and both have an article by me in them !

Model boats features my build of “Little Miss Minty”

British Railway Modelling has a couple of pages I wrote on the subject of lead free soldering.

I am quite smug.

Model boats features my build of “Little Miss Minty”

British Railway Modelling has a couple of pages I wrote on the subject of lead free soldering.

I am quite smug.

Tuesday, June 12, 2007

Loose ends

I’m terrible for starting new projects before finishing old ones. In this I don’t think I’m alone as many friends have the same problem. This means that modelling cupboards of the world are filled up with half-complete projects.

So in an effort to stop,I had another look at Idris this weekend. To be honest I don’t have a lot to do to the boat. Perhaps an air horn on the cabin roof might be a good idea, and some navigation lights but otherwise all I need to do is make a box and then enjoy the model.

As Sunday was nice and sunny the battery was charged and the boat launched on the pool in the garden.

Despite being very light she sailed very nicely. As befits any model boat powered by a dismantled servo the speed was either slow or stop with little in between. Steering isn’t bad and even in reverse the craft is manoeuvrable.

This is not a boat for winds, waves or indeed any sort of weather apart from sunny, still days. However it pootled around the pool very pleasantly for at least 45 minutes with power to spare. Just the sort of relaxing sail to be enjoyed in the evening when the furthest I can be bothered to travel is the bottom of the garden.

So in an effort to stop,I had another look at Idris this weekend. To be honest I don’t have a lot to do to the boat. Perhaps an air horn on the cabin roof might be a good idea, and some navigation lights but otherwise all I need to do is make a box and then enjoy the model.

As Sunday was nice and sunny the battery was charged and the boat launched on the pool in the garden.

Despite being very light she sailed very nicely. As befits any model boat powered by a dismantled servo the speed was either slow or stop with little in between. Steering isn’t bad and even in reverse the craft is manoeuvrable.

This is not a boat for winds, waves or indeed any sort of weather apart from sunny, still days. However it pootled around the pool very pleasantly for at least 45 minutes with power to spare. Just the sort of relaxing sail to be enjoyed in the evening when the furthest I can be bothered to travel is the bottom of the garden.

Sunday, June 10, 2007

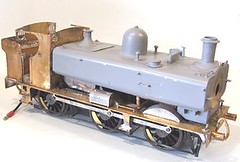

Pannier tanked

Sometimes you just have to admit defeat. While on initial inspection the Pannier locomotive looked promising, I spend a lot of time fiddling and tweaking to get things right. Eventually I spotted the fundamental problem.

When you build an etched model locomotive it’s important to keep checking that everything is nice and square. The builder of this loco didn’t do this and so the cab front and pannier tank back weren’t at right angles to the sides. Of course I should have spotted this earlier – something I will do next time, if there is a next time.

The wonky bits didn’t cancel each other out as they sometimes do. In fact they compounded the problem. You can’t hide the cab/tank join with filler on this prototype, it has to be right. Up to now I had shoved things around to get the front of the tanks in the right place but this twists the footplate so it wouldn’t sit properly on the chassis.

The only way to solve this problem is to remove the offending parts and put them back in properly. That’s a long job with a model this far advanced. It risks damaging the details that has been applied too.

It didn’t help that the owner wanted the model back this weekend – after only being with me for four weeks. I let him know that as it wasn’t as quick a job as I had been lead to believe he wasn’t going to see the model until December. This wasn’t acceptable so I’ve handed it back so he can find someone else to sort the problem. If I were a professional with nothing else to do I’d have done the job to the deadline – probably, although most pro builders have a waiting list of over a year if they are any good.

So that is the end of this project. A bit unsatisfactory (for me) but I am sure I can find something else to do. The stack of railway kits is calling…

When you build an etched model locomotive it’s important to keep checking that everything is nice and square. The builder of this loco didn’t do this and so the cab front and pannier tank back weren’t at right angles to the sides. Of course I should have spotted this earlier – something I will do next time, if there is a next time.

The wonky bits didn’t cancel each other out as they sometimes do. In fact they compounded the problem. You can’t hide the cab/tank join with filler on this prototype, it has to be right. Up to now I had shoved things around to get the front of the tanks in the right place but this twists the footplate so it wouldn’t sit properly on the chassis.

The only way to solve this problem is to remove the offending parts and put them back in properly. That’s a long job with a model this far advanced. It risks damaging the details that has been applied too.

It didn’t help that the owner wanted the model back this weekend – after only being with me for four weeks. I let him know that as it wasn’t as quick a job as I had been lead to believe he wasn’t going to see the model until December. This wasn’t acceptable so I’ve handed it back so he can find someone else to sort the problem. If I were a professional with nothing else to do I’d have done the job to the deadline – probably, although most pro builders have a waiting list of over a year if they are any good.

So that is the end of this project. A bit unsatisfactory (for me) but I am sure I can find something else to do. The stack of railway kits is calling…

Saturday, June 09, 2007

Pannier window

Some things on a model locomotive have to be neat – in fact if you can’t make them neat you’re better leaving them off as the eye spots them and registers a problem. Lines of rivets for example, get ‘em wonky and everyone will point and laugh. Leave them off and the viewer probably won’t notice them.

Guard bars at the back of tank locos are another. On the Pannier they were all in place but wonky. The trick here is to use a spacer behind them and push each one against this so they are all the same distance from the window.

In gauge 1 I was able to use a handy wooden stirring stick purloined from a coffee-house or McDonalds. In smaller scales a bit of cardboard is best but here I needed depth. I suppose that the GWR didn’t space the guards exactly the same as I have but they look the part and were nice and easy to do.

Guard bars at the back of tank locos are another. On the Pannier they were all in place but wonky. The trick here is to use a spacer behind them and push each one against this so they are all the same distance from the window.

In gauge 1 I was able to use a handy wooden stirring stick purloined from a coffee-house or McDonalds. In smaller scales a bit of cardboard is best but here I needed depth. I suppose that the GWR didn’t space the guards exactly the same as I have but they look the part and were nice and easy to do.

Friday, June 08, 2007

Racing again

Expecting a quiet boating session where I could do some testing I was surprised to find half-a-dozen other model sailors at the lake. It turned out I’d managed to arrive at the start of one of the heats in the Slingshot contest.

Since it was my newly painted model I had planned to test I thought I might as well give it a go.

Heat 1: 4 laps in I clipped a buoy on the far corner of the lake. This flipped the boat. A couple of laps later someone else hit me and flipped themselves. To cap it all the first recovery pole I took wasn’t long enough to get the boats and I had to wait for a few laps until the vessels drifted nearer the bank. I did manage a couple more laps before the end of the race.

Heat 2: Well in the lead I’m approaching the back markers and looking for a chance to overtake. On a corner I take the chance to run inside another boat, clip it and flip over. Recovery takes a few moments but the model won’t start.

The trick as far as I can tell is to stay out of trouble. The eventual winner didn’t do anything spectacular, in fact much of the time he was at the back of the pack, but he kept going.

After a night indoors the Slingshot has dried out and seems unaffected by its soaking. Better luck next time ?

Since it was my newly painted model I had planned to test I thought I might as well give it a go.

Heat 1: 4 laps in I clipped a buoy on the far corner of the lake. This flipped the boat. A couple of laps later someone else hit me and flipped themselves. To cap it all the first recovery pole I took wasn’t long enough to get the boats and I had to wait for a few laps until the vessels drifted nearer the bank. I did manage a couple more laps before the end of the race.

Heat 2: Well in the lead I’m approaching the back markers and looking for a chance to overtake. On a corner I take the chance to run inside another boat, clip it and flip over. Recovery takes a few moments but the model won’t start.

The trick as far as I can tell is to stay out of trouble. The eventual winner didn’t do anything spectacular, in fact much of the time he was at the back of the pack, but he kept going.

After a night indoors the Slingshot has dried out and seems unaffected by its soaking. Better luck next time ?

Wednesday, June 06, 2007

Dirty Carb

My Type 2 is running terribly. It can’t still be muck in the petrol as the tank has been treated and the fuel in the filter is nice and clean. This leaves dirt in the carb as the only possible problem.

I did try adjusting it but nothing seemed to make any difference. A quick look in Bentley indicated that there must be muck in the idle circuit as the van would run, albeit with little power, but not idle after the choke went out.

With the carb on the bench I sprayed cleaners in all the orifices and eventually it found its way around the passageways OK – except the one into the accelerator pump.

An overnight soaking allowed me to drill the silt out of the hole but I’m not sure how big the hole should be so don’t know which bit to use to finish it off. Hopefully the Type 2 mailing list will be able to help.

I did try adjusting it but nothing seemed to make any difference. A quick look in Bentley indicated that there must be muck in the idle circuit as the van would run, albeit with little power, but not idle after the choke went out.

With the carb on the bench I sprayed cleaners in all the orifices and eventually it found its way around the passageways OK – except the one into the accelerator pump.

An overnight soaking allowed me to drill the silt out of the hole but I’m not sure how big the hole should be so don’t know which bit to use to finish it off. Hopefully the Type 2 mailing list will be able to help.

Tuesday, June 05, 2007

Holiday souvenirs

Holidays are great. A few days to unwind, forget your cares and get a break from work.

Of course the keen model maker never rests. He or she sees the time as a chance to plan a new project or research for a current one. Many even take a little box of tools and a simple job to while away quiet evenings when it’s too cold for the beech and all attractions are shut.

My camera was put to work collecting details of fishing boats for a future model, currently number two in the queue for boat kits. I struck lucky and in Brixham harbour found exactly the sort of boat I was looking for. Now I know what the parts look like, scratchbuilding them will be soooo much easier. Of course I need to work out where to get 1/12th scale netting from.

Mooching around the shops selling seaside souvenirs I also found a model boat. Not suprising really as half the output from China these days seems to consist of wooden models to adorn your mantelpiece and gather dust. This though is a different proposition. A nice resin model of a mdern-ish fishing boat. It’s pretty close to 3mm scale as well. All this for £1.99 – what a bargain.

OK, so the details aren’t exactly right and some of the painting is iffy or peeling. Nothing there though that can’t be easily fixed.

Of course the keen model maker never rests. He or she sees the time as a chance to plan a new project or research for a current one. Many even take a little box of tools and a simple job to while away quiet evenings when it’s too cold for the beech and all attractions are shut.

My camera was put to work collecting details of fishing boats for a future model, currently number two in the queue for boat kits. I struck lucky and in Brixham harbour found exactly the sort of boat I was looking for. Now I know what the parts look like, scratchbuilding them will be soooo much easier. Of course I need to work out where to get 1/12th scale netting from.

Mooching around the shops selling seaside souvenirs I also found a model boat. Not suprising really as half the output from China these days seems to consist of wooden models to adorn your mantelpiece and gather dust. This though is a different proposition. A nice resin model of a mdern-ish fishing boat. It’s pretty close to 3mm scale as well. All this for £1.99 – what a bargain.

OK, so the details aren’t exactly right and some of the painting is iffy or peeling. Nothing there though that can’t be easily fixed.

Monday, June 04, 2007

Pecorama

The lack of blog postings over the last few days is due to me being on holiday in Paington. Sorry if you were bored and needed your latest fix of my model making exploits.

My hosts were keen to show me around Devon and being a railway modeller, one of the places to visit is Pecorama.

Now I have known of Pecorama for years. It’s home of the great model railway track manufacturer Peco. Since the 1960’s they have advertised in the Todeller with a picture of the building frontage. I always thought it looked quite impressive. Very 60’s in an almost Gerry Anderson sort of way.

There is promise of a display of model railways as well as a 7¼ inch line. Something for all the family although I confess that I had a feeling the experience would have rather too many “Look a train moving, isn’t it cute” moments for me.

The other reason I was interested in going is that Pecorama is in the village of Beer. I like Beer and find the name amusing in the way that all tourists will and all residents won’t.

So we drive up the hideously steep (1 in 5 I think) hill on a sunny Saturday afternoon.

And it’s shut.

What sort of tourist attraction closes at 1pm on a Saturday during the peak tourist season ? This one obviously.

Still, the main building looks just as impressive as I thought it would which is a small consolation.

My hosts were keen to show me around Devon and being a railway modeller, one of the places to visit is Pecorama.

Now I have known of Pecorama for years. It’s home of the great model railway track manufacturer Peco. Since the 1960’s they have advertised in the Todeller with a picture of the building frontage. I always thought it looked quite impressive. Very 60’s in an almost Gerry Anderson sort of way.

There is promise of a display of model railways as well as a 7¼ inch line. Something for all the family although I confess that I had a feeling the experience would have rather too many “Look a train moving, isn’t it cute” moments for me.

The other reason I was interested in going is that Pecorama is in the village of Beer. I like Beer and find the name amusing in the way that all tourists will and all residents won’t.

So we drive up the hideously steep (1 in 5 I think) hill on a sunny Saturday afternoon.

And it’s shut.

What sort of tourist attraction closes at 1pm on a Saturday during the peak tourist season ? This one obviously.

Still, the main building looks just as impressive as I thought it would which is a small consolation.

Subscribe to:

Comments (Atom)