Once people get to know you are a railway modeller it’s amazing how many “come out” as modellers themselves. The conversation usually starts along the lines, “Well I’ve got a layout in the loft you know. It’s not a very good one but…”

Obviously they don’t want to reveal themselves to “normal” members of society since building model trains is a terrible thing to admit to. Let’s be honest, given the choice between a convicted rapist and train-spotter as dinner guests, most people would choose the former. Railway modellers aren’t quite so reviled but it’s not a huge difference.

Anyway, once they’ve outed themselves you often get requests for help. Hopefully you escape the “opportunity” to go around and built their layout for them, most of the time it’s wanting help getting locomotives to work. Sometimes these are favourite models that have mysteriously stopped operating and the owner doesn’t know what to do next. Perhaps the local model shop, if there is one, will be approached but the proprietor will want money for his time and effort and so the model will be removed and put aside to be fixed, “one day”.

This probably sounds really ungrateful. After all we should all be happy to help out our fellow man and I like to think I do my share of this. If you genuinely can’t fix it and can’t afford to get it fixed then I’m there. I won’t take the work away from the local shop though as he needs to make money to stay open – most shops are plagued with people after free help who then go elsewhere when it’s time for the big ticket purchases.

The worst offenders are the pains who buy junk from a local swapmeet and then expect it returned to mint condition for no money. I know they helped contribute to the demise of one local shop years ago. We British love a bargain but often fail to understand the difference between something that is cheap rubbish and reasonably priced, but slightly more expensive, quality items.

How fun it must be to be behind the shop counter after an event when a “modeller” comes in with the latest knackered offering bought for a few pounds at weekend and they wonder, “if you could just take a look.”. Best of all, while you prod at the lifeless specimen which was sold off for a good reason they tell you about the latest Hornby model they bought online or mail order for a few quid less than the ones on your shelves.

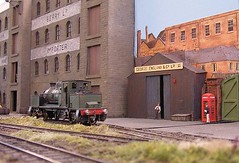

Anyway, getting off my hobbyhorse, last weekend I had the chance to try and service some N gauge items for a friend of my Dad. The gentleman planned to put them through a local auction as he was downsizing and needed to concentrate on the OO collection.

Now he had an idea of values and these were scary. The other thing I hate about this job is fiddling with stuff that I can break and demolish it’s worth. In fact I nearly had to buy one model, A Farish West Country, when it went back together wrong and jammed. The chassis was half in and half out of the body and not moving. Fortunatly it went back together and I was saved.

In the end the auction man gave what, in my opinion, was a very low estimate but I’d had the sword of expectations hanging over me while wielding the screwdrivers.