...or stuff I bought 'cos it interested me even though I have absolutely no use for it.

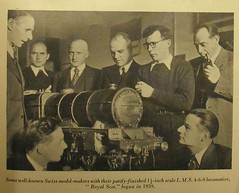

...or stuff I bought 'cos it interested me even though I have absolutely no use for it.The Wilro kit is old. I'm not sure quite how old it is but I would guess 1960's. There were quite a few kits to make the Airfix plastic kits work available then - I have a Perfecta powered Pug somewhere - and this is a really nice one.

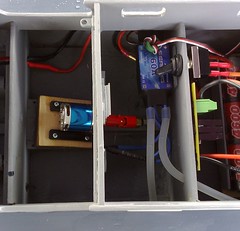

In the box I found:

- Some instructions produced on a typewriter and then banda duplicator

- A K's 5-pole motor

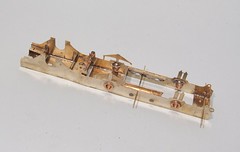

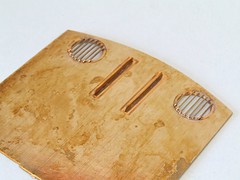

- A very nice whitemetal chassis with pre-fitted axle bushes

- Romford driving wheel conversion kit No.7

- Some gears

- A packet of whitemetal bits for the pony trucks

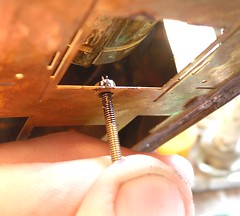

A nice touch is the pre-drilled bullhead rail supplied to act as con-rods. I've done this in the past but am a bit surprised that anyone actually manufactured and sold such a thing.

At the moment I don't have a clue what I'm going to do with this kit. It seems a shame to build it just for the sake of it but then , the kit was designed to be built. For the minute it can live in the cupboard as a curiosity, part of the collection of interesting things. After all it's not like I'm short of projects !

Update from the fount of all knowledge that is Colin Snowdon:

If this is an origional Wilro kit you should find that one set of wheels has a slightly larger bore than the other set (working 3 and three as a set). There will also be a length of stiff but flexible stuff which looks like paper, this is the insulation. To fit you wind a section of the paper cut to the exact length round the axle and push the wheel on over it. Too short, it arcs between the axle and the wheel, too long, and the wheel runs egg shaped or breaks as you fit it. I had one for a pug which contained spoked wheels as there were none of the correct type and being a touch earlier than yours had bronze bushes to fit to the frames. These kits were for Kitmaster kits i.e. pre Airfix and came for several of the kits.