Last week,

Chris Nevard wrote a post about trying a realistic sized project. I popped a comment on the bottom but as I typed, I quickly realised that I was going to write loads, and if I'm doing that, it can go on

my blog.

Chris's example revolves around a beginner approaching him at a show saying he was going the build 'Caerphilly in P4'. I don't know the station but Wikipedia says it was a 4-way junction which means lots of track, lots of trains and plenty of operation. Basically a great model to see at a show if it's working properly, but a heck of a challenge to build, especially if you've never seen a bit of Peco before.

Over-ambition seems to be a perennial problem. I have lot count of the number of people who have talked about starting a model railway but after a few minutes it becomes obvious that they want to build Kings Cross but never never hammered in a track pin. The problem is probably that they have seen big layouts at shows and want a bit of the same excitement. Who doesn't love to see long trains trashing round, appearing and disappearing from all directions ? And why doesn't the idiot behind the little shunting layout realise that that's what they are going to build and not some 6 foot long bit of wood with locos pottering about.

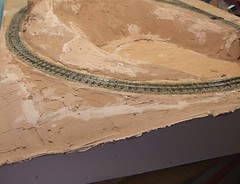

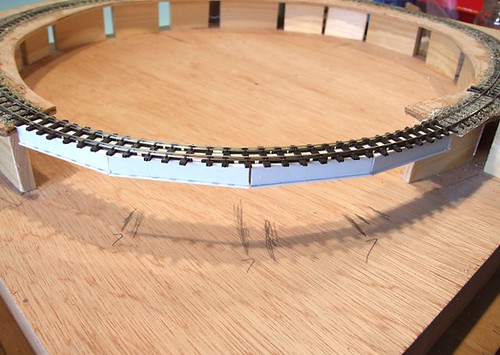

Well, for once the idiot behind the shunting layout knows more than he is credited with. You see, behind the enormous roundy-roundy layout is many thousands of hours taken up with building wooden bits, laying track, ballasting the same and then wiring it up. On a big layout that can 2 or 3 years before a train turns a wheel in anger. That 2 or 3 years is pretty solid model making time too. If you decide that you can't face another Sunday of picking stones out of pointwork then it can be 4 or 5 years, of over a dozen judging by one pair of blokes I spoke to at a show recently.

Big layouts really need big teams of people working on them.

The L&WMRS layout "Clarendon" is a big P4 project, certainly one of the largest and most complex on the circuit. It is also the modelling output of a team of experienced modellers. 10 years worth of output. A long modeller can multiply this by 10 to get an idea how long it could take to achieve the same result.

I suppose it's all down to what you enjoy. If operation is your bag then some Peco track and a big pile of RTR trains would be the best bet. You can nail your rails down quickly and if the wiring goes OK, start playing withing a few months depending on the complexity of your plan.

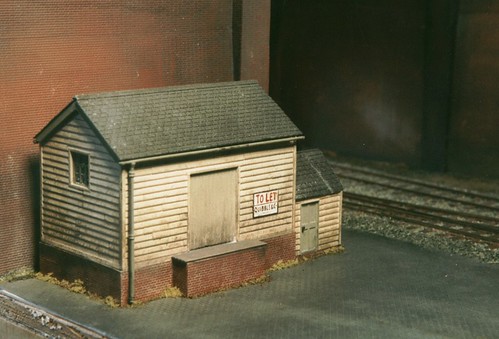

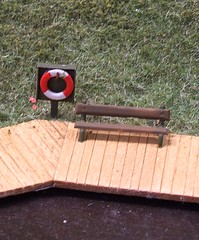

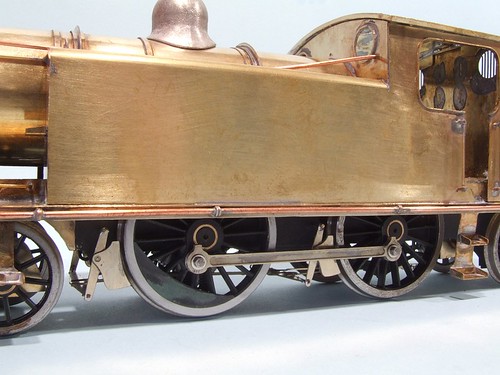

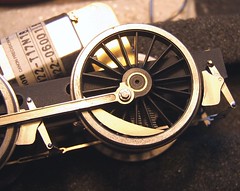

On the other hand, if model-making is your thing then a small layout will give you the chance to see the results of your labours come together reasonably quickly. You can hand build absolutely everything if you want but try to avoid having to spend too long on any single aspect. That way leads to disappointment and abandonment.

You may simply enjoy planning layouts. Many people enjoy using Templot to layout huge models and realistically have no intention of building them. Putting a point in place on screen is far removed from making it up from 50+ components and then trying to make a locomotive run over it.

"But I'm special" I hear you cry, "I have the commitment and enthusiasm to build a massive solo project from start to finish."

Well done, I reply, but think of this, you might be able to build the model (but I bet you won't) but can you move it on your own ? I know one massive, largely solo, project that suffered because it's builder had very limited help putting the layout together. The result was impressive but when it came to going to a show, there was no ready team to put the thing in a van and set it up. Operating required at least 5 people too. The result was frequently a group of operators who didn't have the same feeling of ownership of the model that they would if all had contributed to the building.

And even bigger problem was that the model was so large it could only be set up at shows so never got the proper de-bugging it needed. This resulted in large crowds sometimes watching a big model with nothing running at all.

I suspect I'm wasting my time though. No one looks at the Triang Book of Plans and wants to build number 1. We all aspire to number 22 with a four track main lines and 6 different trains operating at once. Even me.