How's this for timing. We reach the last day of 2011 and I put the finishing touches to the Ford Truck.

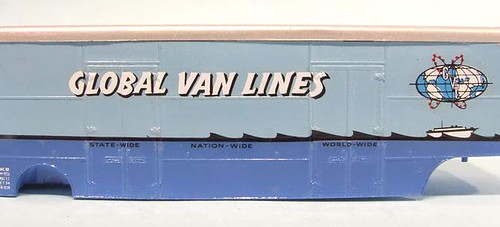

After letting decals dry, the model was given a blast of satin varnish to seal them in and tone down the sheen of the sides. I know the real thing would have been gloss painted, although the paint probably wouldn't have held its shine like modern ones do, but in my opinion, satin looks far more realistic for a miniature.

Sheen was a problem with the black paint that followed. Brushing Humbrol is normally simple but for some reason the stuff insisted in drying with an eggshell finish. A good stir and second coat sorted this out which was a relief. Mind you, the first go looked annoyingly good with not a brush stroke to be seen !

Finally, the cab glazing was put in with Krystal Klear. Not perfect, but adequate for this model. I'm really surprised that the kit didn't come with clear plastic parts for this, it would certainly have been easier. The windscreen was too large and curved for the glazing liquid to be placed in with a cocktail stick or small screwdriver - the paddle end of the Tamiya paint stirrer did the job though. Mind you, even that took a couple of attempts.

Were I to build this model again, the biggest change I'd make to the process would be spraying in matt rather than gloss paint. I think the finish would be better (no dust or paint collection around detail) and I could go over it with acrylic gloss varnish to give the transfers somewhere nice to sit. Even though there would be a subsequent satin coat, the final paint thickness wouldn't be any greater as I had to put plenty of base colour on with the poor coverage of the gloss.

Anyway, that's the last project of the year. Time to get back to something serious now. In the meantime, Happy New Year everyone.