Now GW Models do produce a version suitable for the larger scale but it is £150, which is rather a lot for the occasional model. Mind you, like all their products, it is a beautiful piece of kit and worth the cash.

A phone call (no web site here than you, this is a proper traditional engineering company) to the proprietor was instructive. The tools for the G1 rivetter won't fit in the standard one I own. However it might be possible for me to do something myself, he could supply a couple of anvils for a fiver which I could drill out , harden and then try in my machine.

Off went the cheque and few days later the anvils turned up in a jiffy bag complete with some handwritten instructions. Following these I drilled the hole out to 1mm and then hardened the steel by heating it to cherry red and dropping the hot lump in some oil to quench it. Not having done this before, I used a small pot of oil left over from an oil change on my camper van. The big surprise (for me) was the colour change in the metal. It went from a shiny

silver steel colour to a shiny black. The same colour as the anvils supplied with the tool in the first place, which I guess means I've done something right.

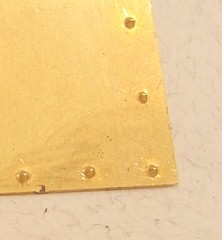

silver steel colour to a shiny black. The same colour as the anvils supplied with the tool in the first place, which I guess means I've done something right.In use, the tool produces lovely domes in the metal. You have to use the punch intended for forming raw metal rather than the half etch version - that's too sharp and either gives a tiny lump or punches clean through the metal.

No comments:

Post a Comment