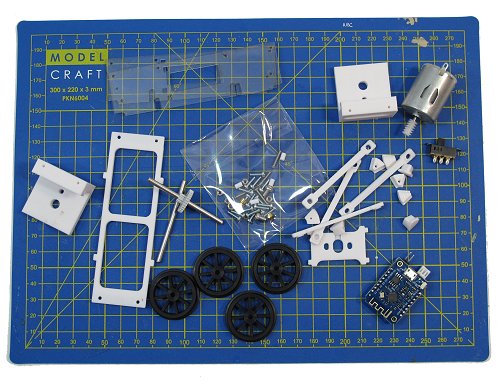

In thoery, assembling the Boot Lane chassis is a screwdriver job. Acrylic sides are screwed to 3D printed spacers. Not quite idiot-proof, but if you read the instructions carefully, then hopefully not to bad a job.My Dad managed, with a tiny bit of assistance, to put the working of his Rose together, and it's the first time he's ever done this sort of thing.

The motor fits nicely into it's cradle, and everything fits perfectly. Getting the spacer the motor bolts on to the right way up is essentail - there is a groove to accomodate the gear wheel that should be at the bottom (the chassis is upside down in this photo) or it won't fit later.

Biggest surprice so far, how far the screws go into the spacers. Lots of turns of the big screwdriver, in fact a small powered version wouldn't be a terrible idea for this job.

4 comments:

Nice update, Phil - this is an interesting kit, I love that more kit manufacturers are using a combination of traditional materials and 3D printed (and laser cut) parts. Is a kit like this something we're likely to see in smaller scales, do you think? Could it be done?

Cheers,

James

The answer to mixed media in smaller scales is yes it's feasible and has already been done many times. Not wanting to blow my own trumpet too loudly, but here are two examples from OO9 of kits I've designed that use a combination of 3D printing (including brass in one case) and etched parts:

24hp Hudson-Hunslet diesel locomotive

Alan Keef K12 diesel locomotive

The only issue with the smaller scales, as Phil can attest having helped to assemble one of my 24hp Hudson-Hunslet models, is that the smaller parts make life a bit more tricky and fiddly, but the approach is the same.

Thanks Mark, those are both lovely. Good to know this is doable (if tricky) in smaller scales. 3D printed brass is intriguing - I need to look that up

The details on the 3D printed brass chassis are buried in this post on my blog. To be truthful it's not printed brass as such, but rather a traditional lost wax brass casting. From my point of view though it feels like a 3D printed brass as I send of a 3D file and they send back the brass part with the actual process completely hidden from view.

For some metals they do actually print the part though rather than doing a lost wax casting. This is a cheaper process as well so can work nicely. I've used this for 3D printing stainless steel parts that act as weights inside small models.

Post a Comment