A daily updated blog typed by someone with painty hands, oil under his fingernails and the smell of solder in his nostrils who likes making all sort of models and miniatures. And fixing things.

Tuesday, September 30, 2008

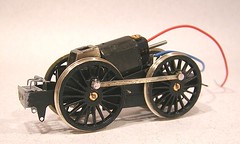

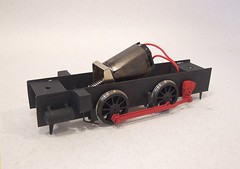

Chassis with wheels

Not sure that there is much that can be done about this. A thinner motor might work but could be a bit underpowered. A taller gearbox would help but the space above the motor is limited. Of the two I suspect the later is a better bet if you can get a decent ratio and not end up with a thoroughbred that travels at shire horse speeds.

Monday, September 29, 2008

Banbury Model Railway Show 2008

3 quid (2.50 for old people) to get in give you a free programme and entry to a model railway show in a school. The event fills the main hall and 5 classrooms. 14 Layouts. 11 traders. 1 long corridor with a tanoy playing music from (I think) "That's what I call 70's porn film soundtracks Volume 1".Rather than try

and describe everything in details I'll just enthuse about a few of the exhibits that caught my eye.

and describe everything in details I'll just enthuse about a few of the exhibits that caught my eye.First up was Rowell Sidings, a OO layout which made very effective use of SuperQuick cardboard buildings. With the rise of the pre-painted resin model these have lost favour but here you could see just how well they can work if put together nicely and accessorised with suitable posters and street furniture. Also of note were the baseboards that allowed the line to cross over a road with the drive to the station rising up from this.

In room 2 there was "A taste of the Algarve". Since I've never been to Portugal my opinions on the effectiveness of the buildings and scenery are entirely based on the stuff seen on the telly and in the papers. That said, it looked very good. The architecture was right. The streets were higgledy-piggledy. All the walls were white stucho and the tiles were orangey brown. The model glowed like a sun drenched town should do. OK, the railway side of the display was very limited, just a loop in the station. The running wasn't great while I watched either - but none of that mattered as the wealth of detail rewarded a good look. I'm not one for foreign prototypes but this was great.

In room 2 there was "A taste of the Algarve". Since I've never been to Portugal my opinions on the effectiveness of the buildings and scenery are entirely based on the stuff seen on the telly and in the papers. That said, it looked very good. The architecture was right. The streets were higgledy-piggledy. All the walls were white stucho and the tiles were orangey brown. The model glowed like a sun drenched town should do. OK, the railway side of the display was very limited, just a loop in the station. The running wasn't great while I watched either - but none of that mattered as the wealth of detail rewarded a good look. I'm not one for foreign prototypes but this was great. The other stick in the mind model was Two Sisters Farm, a 1/32nd layout based on a Lincolnshire Potato railway. The stock was a bit weird narrow-gaugey but the detail was amazing. Sheds were fully fitted out inside. Tools littered the ground but not in a random way. The weathering was of the highest order. I love this sort of thing - tiny, incredibly detail models where the build has had to make everything.

The other stick in the mind model was Two Sisters Farm, a 1/32nd layout based on a Lincolnshire Potato railway. The stock was a bit weird narrow-gaugey but the detail was amazing. Sheds were fully fitted out inside. Tools littered the ground but not in a random way. The weathering was of the highest order. I love this sort of thing - tiny, incredibly detail models where the build has had to make everything.To be honest, for the last couple of years, if Banbury hadn't been a short run down the road I'd probably not have bothered. This time it was a good 'un. I've missed ouyt several quality layouts and not mentioned the trade at all but what was there more than made it worth the trip.

Anyway, never mind the words, look at the pictures.

Sunday, September 28, 2008

Markits Gearbox

The motor mount holes have to be drilled and reamed out - 4 are provided and I used the inner pair. I also snipped off the "ears" that allow the motor to be mounted flat as these would get in the way of the slimline chassis sides.

I only had one problem - the worm was intended for a 2mm shaft and the motor I was using had 1.5mm. Obviously this has occurred before as in my spares box was the correct version, now replace in there by the one supplied.

The mesh was excellent straight away and the axle turned in it's (supplied) thin bearings freely and with no tight spots.

I may have to hack away a bit at the metal to get the 'box into the chassis but there is plenty of meat to allow this without affecting anything.

Saturday, September 27, 2008

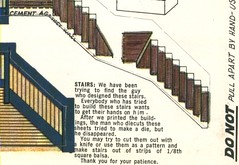

Instructions

Looking at them he found this fantastic note - you may need to click on the picture to see it in its full glory. This alone is worth the purchase price !

Oh, and the line of text up the side says: DO NOT pull apart by hand - use a sharp knife. Good advice for all walks of life.

Friday, September 26, 2008

Blown filler cap

My plan was to see how long the engine kept going so I could plan future trips. On two tablets of fuel and 60ml of water, I managed 21 minutes. At this point the engine was obviously losing power and in danger of stalling so I pulled it to the bank and tried to put out the fire by blowing down the chimney.

On doing this the water filler popped off. Fortunately it fell onto the landing stage.

Obviously what had happened was that the boiler had run dry. The fuel tablets last urges were enough to melt the solder and the remaining pressure enough to flip the filler, which is simply soldered to the surface of the boiler, off.

During the week I manged to re-fit the filler, albeit not quite as neatly as before. Doing this without dismantling the cladding meant I managed to singe the wood a little too. This will give the boat character I think and not just a memento of my laziness...

A steam test showed that there weren't any other leaks so last night the model took another turn around the water. This time I limited the run to 15 minutes and all was fine. So now I know - quarter of an hour an no more, or it's the soldering iron for me !

Thursday, September 25, 2008

Primed tender

Inside the valances are a set of half etch markers to indicate the position of the side frames. These are soldered in place and then the axleboxes, equalising bars and springs fit on the outside. To fit the equalising bars (I think that's what they are anyway) I use a bit of scrap etch to space them away from the valance otherwise you miss the separation that shows up in the photographs of the real thing.

Priming is as usually carried out using an etching car primer. This showed up some minor tweaks would be required although surprisingly little around the flare.

Wednesday, September 24, 2008

Tender flare

So I fitted the sides which isn't too difficult except this is a but joint visible from both sides. The the back. This has to be joined in the same way BUT you have to bend and trim the corners as well.

In the corners I'll admit to be completely unscientific. Rather than spend hours trimming and fitting the brass I get it near enough and then blog a load of solder all over it. This is then carefully (!) filed into shape. Sometimes this gets too thin and I have to fill it up again and start over. Sometimes it works well, sometimes there is a lot of swearing and grumpiness. Bit like life really.

Tuesday, September 23, 2008

Dunalastair tender frame

To re-invigorate my interest in the model the packet containing the parts for the tender (tender parts - arf !) was opened and started.

First up the footplate has the buffer beams bent down and then a frame is folded up and attached to give the structure and support for the bodywork. This give the ski-ramp top you can see which will eventually disappear under a coal load.

In 7mm scale those holes would be easy to poke a soldering iron through to make the joints. In HO they are a bit small in places and the iron hasn't shrunk.

Monday, September 22, 2008

Lighthouse

Taking up the story from last time: The clear lamp part at the top has been wrapped with thin plastic with a rectangular hole cut in it. A raised area, which I like to think represents a wooden panel, complete with access door was fixed to the front. The prototype I was following has a recess but I don't have a way of cutting glass so improvised.

The dome was segmented with microstrip lines that were carefully marked out. I bent a paper strip around the outside and measured the overlap. Then subdivided this and transferred the marks back to the dome. That way each "slice" is identical. I know it doesn't matter but you'd notice if I got it wrong. The lines represent seams in the roofing lead.

Next came painting. The window was masked carefully and the whole building sprayed with car primer. It was only really at this point I had any idea if this building would work. Since it seemed OK, a couple of coats of Humbrol 147 (pale grey) were followed by lines in green. Finally washes of dark grey and dark brown finished the job. For some reason the paint on the "wood " strip crinkled slightly, I suspect a reaction between the enamel paint and acrylic primer but can't be sure. It looks good though, properly weather beaten.

Anyway, I like it. On the layout it's presence gives depth to the board and certainly shows I do a bit of scratchbuilding.

Sunday, September 21, 2008

Shenfield Show

What better way to start a Saturday morning than to rise slightly before the lark at 5am, load a model railway into the car and drive for a couple of hours down the M40 and M25.

Yes, the exhibition season is upon us again and our first show in the autumn session was at Shenfield for the Mid-Essex exhibition. Although only a one day event we have taken all three layouts there because it is a nice day out and we're well looked after by the organising club. The rest of the exhibits are of a reasonably high standard and the trade is good too. It's an odd venue - the show is bisected by a swimming pool which meant the organisers have to issue tickets to traverse the corridor between the two halves. There are two big halls though so only a couple of classrooms are needed imparting a better atmosphere than that at events made up of a series of small rooms.

Access for set up was good and we found our spot in the hall without difficulty. You think this would always be the case but some venues are like mazes and you're more likely to find a Japanese soldier who thinks the war is still going on than anything to tell you where to put the train set up. Others are big halls which can be even worse as there are no landmarks to guide you.

Anyway, once set up we toured the halls to see what goodies were on sale and who the public would compare us to. In the same hall we were next to a small EM gauge station (Rixworth Green), 016.5 model (Getsup St Anne), wartime layout (Manston Airport) and brewery (Blackwells Brewery Co - look at the initials Ho Ho). All of these looked to be OK especially the wartime model and brewery which I've seen before any enjoyed in the past.

The day was busy, numbers were well up apparently, and there were plenty of questions from the crowd. At least one pair of gents stayed with us for over an hour chatting and looking the model over (hello to those who admitted they read the blog, nice to meet you). By the end were pretty hoarse ! This is great - operating the layout is OK but chatting is the real reason we like to exhibit models. You get to learn a bit, help others a lot and laugh loads. Of course there are some who take it too seriously and wander around looking like they are are funeral with toothache. While I'll do everything properly (no gimmicks or silliness on the model) it is supposed to be a hobby and fun.

I missed one photo during the day. On an American prototype layout (Purcell) in one hall there was a lovely visual joke. A line side hoarding advertised "Trailers for sale or rent" and the hotel next to it offered "Rooms to let 50c" in larger painted letter. Funny and subtle.

Our crowd stayed until around 4pm when we started to have time with no one in front of the model. The appearances of paying public became more sporadic until abut 5.30 when it seems they had all gone home. Everyone stayed put until the 6pm finished although there were signs of heavy preparation for packing up and perhaps the odd bit of light dismantling. Certainly had anyone fancied trying to see the show in the last 10 minutes (it happens, honest) they wouldn't have seen as good a display as at 10am. Mind you if that's your game it serves you right.

Flockburgh ran well all day. Perhaps it was the chlorine in the air from the pool but there wasn't a hint of dirt on the track by the end. Some of the locos were bit sticky but I put that down to the long lay up between events. Our 2F was a casualty - for some reason it was working far worse than normal, stalling and the tender kept spreading itself over the pointwork. It was quickly relegated to the engine shed siding and will be attended to before Uckfield, but then I've said that before. Having said this everything has been put away now and won't be touched in the hope that if we leave well alone...

As usual there was much chat with the other exhibitors, especially our neighbours from Rixworth Green. Apparently the indulge in a bit of 3mm scale modelling too and I coveted my J50, which I promptly shut in the display case for security reasons. Mind you, anyone who can assemble a Jidenco kit for a Beattie Well Tank wouldn't have any trouble with the Finney kit !

Saturday, September 20, 2008

Classic Train & Motor Bus - Leamington Spa

It's very remiss of me not to have made this post earlier. Classic Train and Motor Bus in George Street, Leamington Spa, is my local model shop and a very good one it is too.

It's very remiss of me not to have made this post earlier. Classic Train and Motor Bus in George Street, Leamington Spa, is my local model shop and a very good one it is too.You will surmise from the picture that the shop isn't in the high street and you'd be right. In fact like the best model shops it's bit tucked away but well worth the effort to seek out. The walk is short - about 5 minutes tops from the Jephson Gardens in the middle of town where you can leave the family.

Inside, the shop is tiny. And packed with stock. Lots of RTR is available along with loads of kits of all description. Most of the stock is OO and N gauge but odds and sods of other bits turn up occasionally. There is a selection of second hand as well.

The best thing about this shop is the bits. One wall is covered with an ever changing display of kits and bits. There are also several large drawers that just demand digging through to unearth gems.

If you can't find what you want, just ask Mark and he'll be only too happy to order it for you.

More details and a map in this UK Model Shop Directory entry.

Friday, September 19, 2008

Lighthouse under construction

The trouble with these are that they are round and I don't own a lathe. I did look for some hexagonal prototypes but couldn't find anything. Presumably in real life round stands up better to the sea conditions and isn't that hard to build. You'd think designer would consider the needs of modellers, but no.

Anyway, a trawl of junk and charity shops gave me some oddments to "kitbash" into a representation of the building. The base (purple in the photo) is an upturned glass scented candle holder. The wax came out easily enough but the wick stayed put so I've left it alone.

To this I stuck rims of plasticard using superglue. The top is plastic trimmed back to the rim when dry. Humbrol filler finished these bits off neatly. Gluing to glass isn't easy and I had to do it in stages, clamping every so often. A bit more attention paid would have revealed that the colour is a translucent paint and probably should have been scraped off before work started but it didn't so it wasn't.

To this I stuck rims of plasticard using superglue. The top is plastic trimmed back to the rim when dry. Humbrol filler finished these bits off neatly. Gluing to glass isn't easy and I had to do it in stages, clamping every so often. A bit more attention paid would have revealed that the colour is a translucent paint and probably should have been scraped off before work started but it didn't so it wasn't.The top with the light is a cap from a PVA glue bottle found in a stationery shop. I'm not sure how long the glue will last without this but It was worth buying for this moulding. Capping this and providing a dome is the bowl from the half teaspoon size measuring spoon from a set bought in cheap shop. For 99p I have a set of graduating domes for other projects too !

There's obviously some work to do and I'll post pictures of the finished item after the weekend if I'm happy with the result. If not we will never talk of this again...

Thursday, September 18, 2008

Preparations

Sometimes, care an attention to detail when building things pays off. If I sound smug then it's 'cos I am. We set Flockburgh up this morning, the first time I've been on its legs for months, to test it in preparation for the weekend at Shenfield - and everything worked.

So there was a sticky point motor but I waggled that back and forth with my hand and it was fine after this.

A couple of dry joins were found too but heating them with the special exhibition soldering iron (it has over 6ft of lead so I can reach the baseboard easily with the plug on the floor) sorted these out.

A couple of the locos were sticky after the long lay-up but a waz (technical term) up and down the fiddle yard freed them up.

I just hope everything works as well after the early morning trip around the M25 !

Wednesday, September 17, 2008

Chain fence

Flockburgh is due to go to Shenstone show on Saturday. Despite the gap in events we still haven't made much progress on the new scenic end to the layout so I've set it up for a few days to have a fiddle.

Flockburgh is due to go to Shenstone show on Saturday. Despite the gap in events we still haven't made much progress on the new scenic end to the layout so I've set it up for a few days to have a fiddle.One of the obvious problems was that of our 3mm scale people falling off the end of the prom. Since we don't want them hurting themselves I've put a chain link fence in place. Of course this being a model railway, it's not real. The posts are Peco track pins and the chain, ordinary thread.

The tread when tied in place pointed in all directions but down so I soaked it in superglue a section at a time and used tweezers to pull it into a more realistic direction. Them because this made everything shiny, painted it all in weathered black.

It's only a little detail, and not one most people will take any notice of but I like it and since it's my train set, then that's what matters.

Tuesday, September 16, 2008

KMBC Sunday Lunch 2008

A strange thing happened on Sunday. Sunshine. Hot sunshine. And no rain.

A strange thing happened on Sunday. Sunshine. Hot sunshine. And no rain.Monday, September 15, 2008

Sooty sails !

Having grabbed a frequency. I loaded up with 60ml of water and 2 whole tablets of solid fuel, lit this and took the boat down to the landing stage. Raising steam seemed quicker than normal, certainly not the five minutes I've waited in the past - or maybe I was just chatting so didn't notice !

On the water the engine ran well with the model pootling around within reach of a boat retrieving pole. I did make a few trips further from the bank but decided discretion was the better part of valour on the first run . The controls were passed to Derek while I filmed the model and took some pictures.

After 15 minutes or so I brought the model in and checked the fuel - still about a quarter of each tablet was left but I blew these out and let things cool.

Once we packed up I tried a more ambitious trip around the edge of the lake on both directions with no incidents. Again, the engine ran well with no problems and most importantly, no stalling. I left the lake a very happy model boater.

During the sail it became apparent that there are a few jobs to do:

- The model has a slight list. A bit more weight on the side with the figure should sort this. The hull is buoyant enough to handle this with ease.

- The trim needs adjusting again. We still pull to the right a lot, more than the trim on the transmitter can deal with.

- The locating pins in the baseplate have been sliding down, making the boiler unstable. Some glue able to take the heat is needed.

- One member who knows a lot about model steam engines suggests that for single cylinder oscillators, a very weak spring to pull the cylinder over can help if the model stalls. The spring pulls the cylinder to the point where it will restart. I'll investigate this IF I have problems. For the minute I'm happy with the way its running so I'll leave well alone.

Sunday, September 14, 2008

Crossing Shanty in print

I'm in illustrious company as Gordon Gravett tells us how he scratch builds buildings in 1:50 scale, a rather more impressive feat than my sticking some bits of laser cut ply together !

Saturday, September 13, 2008

Rain stops play

So there I am with a big hole in the side of my VW - and a repair panel to fill it with. All I needed was some cooperation from the weather. Which of course I didn't get.

So there I am with a big hole in the side of my VW - and a repair panel to fill it with. All I needed was some cooperation from the weather. Which of course I didn't get.The day was spent dashing out from under the garage roof to take advantage of any moments when the sea wasn't falling from the sky. It's not clever to use electrical equipment in the wet but your standards go down as bit when in the midst of a project. Besides, I was wearing thick leather gauntlets so I'm immune from anything aren't I ?

The hole was tidyed up a lot and gained neat corners and a flat(ish) top. I'm getting good with the angle grinder !

Then during a wet bit the panels was chopped down. Most of it is now spare metal in the corner for future projects. What was left fitted surprisingly well. I even remembered to clean paint off for the welding earth and drill some holes in the flange for plug welding.

Clamped into place the fit was OK but got better when I shuffled it up a bit to overlap the existing side a couple of MM. The panel's not that thick and my van seems to be home for plenty of filler on that side so I think I'll get away with this. It certainly makes the welding easier - in an hour the thing was fitted and I was attacking it with the grinder again.

Then cam the rain. I suppose if I'd set fire to anything this might have helped, but I hadn't, and it didn't. SO I sprayed the job with zinc and as soon as the sun comes back will splodge some filler on. I know it's not perfect and a proper bodywork man would do a far better job. But I did it and this makes me proud.

Friday, September 12, 2008

Whoops, inferno

I was not happy. But knowing it had to be fixed, and in a rather more permanent way than fibreglass and filler would achieve, I arranged to get the vehicle into the repairers to fix this and some of the other issues. The time arranged for the fix dragged on - going along to drop him off and having to come back was the cause of my forklift incident.

To try and speed things up I said I'd cut out the old metal and obtain the repair panel. The last bit was easy, a call to Schofield did that, the cutting was more fun. The idea is to take out metal above any previous repair panel which meant we'd use the entire new one. So I started work with the angle grinder up there.

The rust wasn't as bad as I feared. I had crept no more than 1/2 inch up the metal. The flange at the bottom was a bit holey though. Think lace and you get the idea. With no sign of a trip to the ramp I decided to practise my welding. A couple of hours later the bottom flange had no holes, these had been filled with weld and in one case a new strip of metal. I was pleased. A little victory dance was tempting but resisted.

Filled with confidence I decided to look at the panel. One problem with the original plan was that with the camping interior in place you can't weld the new metal to the floor. I didn't want to take out the sink etc. if I could help it as this is a big job and not easy as the van stands (currently) with the sliding door against a wall so the room to maneuver is very limited.

So, plan B is to shorten the repair panel so the top comes at floor level. That means filling my previous cuts. Well I'd done this for the flange so how hard could it be ?

Initially, not very hard. I filled the slot in a series of blobby welds and ground these down to look OK. Toward the front though a fire broke out. I'd had a few little ones before and just blow them out. This one wouldn't go out the same way though. You see when building the interior we stuffed polystyrene in the walls and that was ablaze. Big time. Flames were visible through the unfilled cuts and smoke from everywhere else. This was not A Good Thing.

Grabbing a small fire extinguisher I covered the area in white powder, squirting it through the gaps to sort the main blaze. The van smelt of melted styrene and the paint had bubbled a bit but otherwise there was no damage.

The back of the sink has now been chopped out and the insulation removed. Welding can now start again. This is one job I'll be glad to see the back of !

Thursday, September 11, 2008

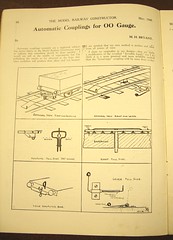

Tension lock archaelogy

Is this the origin of the tension lock coupling now affixed to all OO ready to run models ?

It certainly looks very similar. Funny how people now moan about the thing disfiguring the model. Back then the fact it operated at all must have been a revelation.

Mind you, if we could have shown a just post war modeller a current Hornby product it would have blown them away. It just shows how far the hobby has moved in the last 50 years. Of course if modern modellers had to build all the couplings themselves, perhaps they'd stop whining about tiny errors in the current batch of RTR !

Wednesday, September 10, 2008

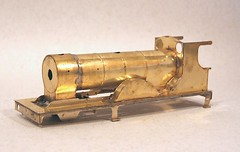

Boiler Fitted...

Putting a wire through the washout plugs gave a handy indication of how accurate the fit was - if the wire was level so were all the other holes. I'd made it three quarters of the way through the tea before I was happy.

Then the smokebox went back and I cleaned up. But I'm still not sure. I think the boiler might go up towards the front but I can't be sure. Measuring the top seems to indicate that everything is OK but sometimes I look at it and see a gradient, sometimes not.

Time for another cup of tea I think.

Tuesday, September 09, 2008

2mm scale Clyde Puffer

Only I could go to a 7mm scale Model Railway show and come back with a 2mm scale boat...

What I have is a very nice little resin kit from Gramodels for a Clyde Puffer. Cost £12.50.

You get a lot of bits for your money but the first thing you see is the hull which is moulded as a single part. It needs some flash cleaning off the bottom but is a good shape and nice and sharply cast. The hold cover is a separate part so you could model it open if you wanted although an interior would be required which extended below the bottom of the waterline hull.

The wheelhouse is an open version with wires cast into the top legs for strength. I've always preferred to give my crew a roof and so added one from a bit of plastic and a couple of extra microstrip window bars.

No railings are included so some were made up from wire. Ideally an etch would be good for this but that would push the cost up and while it's reasonably priced for what you get, the British modeller is notoriously stingy.

Apart from this, what you see is what you get. A few hours pleasant assembly and painting results in a very nice little puffer to add to my collection.

For more Clyde Puffer models and books, try my Puffer pages.

The death of trainspotting ?

How Osama bin Laden killed trainspotting.

This is sad. Trainspotters get a worse press than terrorists or rapists yet they are one of the few rebellious groups left. Think I'm joking - well who are today's' rebels ? Society prefers people to be docile consumers who'll live their lives vicariously though passive hobbies like watching television or football. At best we are allowed to go an buy stuff that has been approved by the media. If it doesn't make money for someone then society and the Government want it to stop.

Monday, September 08, 2008

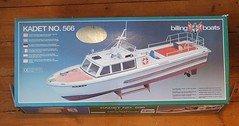

Kadet

This kit is a now discontinued Billings Kadet. It came to me with some MacGregor radio control gear in an eBay auction. I wanted the radio for a vintage boat project and thought I'd sell the kit on eventually. When it arrived though I decided that the model looked so nice I'd hang on and build it myself.

Now I know I've just said no to more second hand kits of dubious parentage but I don't think this refers to Billings. I know their kits can be entertaining to build - the African Queen isn't quite as simple as you'd think for example - but generally they are some of the better ones. This model is apparently even suitable for beginners, which should be even better news for my chances of getting it on the water !

Sunday, September 07, 2008

Pilot Boat - Sunk

You see there was a problem with the "kit". Namely, it was rubbish.

Putting the stand together, I noticed that the hull was not symmetrical along it's axis. Possibly this might have just been down to the flexibility of the vac-formed plastic and if I put a deck on I could pull one side in a bit making it look OK.

So I started trying to work out the deck. But I couldn't. You see the "plans" were, on investigation, little more use than doodles. Across the stern, they were the same as the hull. Along the length, they were a lot too short. And the lines along the sides didn't look like either half of the hull.

The side view made things worse. This was even shorter and also showed the deck should rise toward the bow - but by how much ? With the proportions being out there was no datum to work with. The superstructure didn't match what I had either, but at least it looked like the photos, sort of anyway.

What I need for this boat is a proper plan. If I could get one of those I could make up some bulkheads which would allow me to work out the rise of the deck and incorporate the camber that I'd seen on the other pictures of boats I'd found. But if I did that there was little chance that the plan based bulkheads would fit the hull I had.

At this point it became all too painfully obvious why the model hadn't been built. If I could get the information, scratchbuilding would be a whole lot easier for the quality of model I wanted. The best this thing would be good for is a bath time toy.

I did consider putting the boat back in the cupboard but to be honest I need the space more than a duff kit. eBay might have been an idea but how can you describe something you know to be junk accurately and sell it for enough to make it worth the effort ?

In the end I recovered the shafts and stuck the remains in the bin. All the bits I bought will be used on future projects so long term I've probably wasted less than a tenner in kit and plasticard. Perhaps that's worth it for a valuable lesson learned about buying old projects on a whim.

Which just leaves the Brede kit from the same maker. I've seen this made up and it can look nice. I also have a very detailed plan for the boat from the RNLI so I can make the bulkheads up to get the deck and hull shape right. What's the betting I flog the kit and scratchbuild the boat instead ?

7mm Barclay Diesel

It's finished. After a few little tweaks such as re-glazing a couple of windows and fitting the buffer-heads, the loco has been delivered.

It's a lovely kit and the result is a very handsome model. I think it looks better than the 3.5 and 4mm versions.

At Telford it attracted much favourable comment, although by the end of Saturday no-one had placed an order. Mind you this isn't uncommon with a new model that hasn't received any pre-publicity.  The first time anyone knows about it is when they see it on a stand. At 100 quid plus motor, wheels and gears it's cheap for a O gauge loco but still not an impulse buy !

The first time anyone knows about it is when they see it on a stand. At 100 quid plus motor, wheels and gears it's cheap for a O gauge loco but still not an impulse buy !

The show itself was quieter than normal and those walking around didn't seem to be staggering under the weight of their boxes as normal. Of course we are suffering from a "credit crunch", the BBC reports that croissants are up 47% - a precursor to the end of the world if ever there was one, so that may have affected things. More likely the last few days of heavy rain and floods have dissuaded people from travelling too far. By close of play at 5pm the hall still had to be emptied of modellers with no homes to go to !

Saturday, September 06, 2008

Tool Porn

I have a plan. The day I win the lottery*, I am going to ring up Squires and say, “Send me one of everything in the catalogue.”.

I have a plan. The day I win the lottery*, I am going to ring up Squires and say, “Send me one of everything in the catalogue.”.My name is Phil and I am addicted to buying tools.

Oh yes, I love getting my hands on a new catalogue. Teh Interweb is all very well for ordering and shopping but there is nothing better than leisurely browsing through the densely packed, fully illustrated pages produced by one of our better equipment retailers.

Recently I picked up the book from Machine Mart. It's fat, full colour and printed on very thin paper. That just means more pages and more drooling for me. I find myself examining pictures of machines I 'll never hope to have a need for and reading the specifications. The chance of my workshop ever sporting a lathe, or me acquiring the skills to use one, are very slim and yet I find the section fascinating. Even more remote is my need for a motorised, tracked, wheelbarrow. Doesn't stop me looking at at the details and feeling just a hint of covertness.

Even the simple hand tool sections can turn me into a newbie model maker. The sort who thinks that if only I had one of those, I'd be able to do this stuff so much better (This is called “The search for the Guy Williams soldering iron” – after the legendary Pendon engine builder and the idea that if you have the same tools as him, all your work will be of the same quality regardless of your own skill level). Do I really need more varieties of clamp or will the ones I own already do the job as they have to date ? Well maybe, but perhaps just one of two more wouldn't be a bad idea...

Specialist catalogues are even worse. The Tiranti sculptors book has loads of things I've never seen before in it. My heart knows that there is no place in my life for a potters wheel or kiln and that the casting resins I use are already ideal for the job so if I bought a greater variety they would just sit on the shelf and go off. Doesn't stop the longing though.

Of course this is the point. I know that the descriptions are put together by modern day sirens luring the unsuspecting handyman onto the rocks of financial penury. We all know this and yet we still allow ourselves to be tempted.

There is a darker side to all this. I know of several people who have convinced themselves that they can't start model making until the “correct” toolkit has been acquired. They simply must have 5 varieties of solder before plugging in the soldering iron, and at least three of these too. All this is just an excuse to put off the dread moment when the aspiring model maker has to get his or her hands dirty. Until that point the dream is perfect, everything will go together beautifully. Each locomotive or boat or car assembled will be a museum quality masterpiece that others will gaze on in awe. Once you get started, reality will dawn and the bits won't fit, the joins will be hard to make neatly and square, dust will magically find its way into the paint finish and a hundred other problems will pop up like the creature in a “Whack a mole” game in an amusement arcade. Perhaps the kit can stay in the box for another day while the device that will make its construction that little bit easier is hunted down and added to the toolbox.

Never mind, it's a stage we all have to go through. As someone famous should have said, “Every model starts with a single cut.”

And the new Squires catalogue is out very soon. Something to look forward to.

*Note: I understand my chance of winning have been slightly reduced by not buying tickets on the grounds that my sister inherited any genes the family had for winning things. And if Mr Squires is reading this, don't get too excited. After any relevent lottery, win the first phone call will be to the RNLI to buy them a lifeboat. You get some of what's left.

Friday, September 05, 2008

Switching on and off

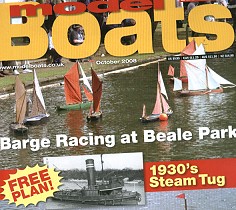

Well, wonder no more. Just head down to the newsagent and obtain a copy of the October 2008 edition of Model Boats magazine. In there you'll find a piece by me (why else do you think I'm blogging it ?) on just that subject. There is a nice photo of my Puffer in there too.

Talking of puffers, a short follow up points people at my Puffer pages where you can find details of models, books and real boats.

Nearly there

A few finishing touches today and then I'm off to Telford !

Thursday, September 04, 2008

Disasters

Disaster 1

Disaster 1The casting on the right is what you get if you touch the casting on the left with too hot a soldering iron. In case you were wondering it's the Barclay locomotive's headlight. And you can attach it with 100 degree solder.

A frantic afternoon 'phone call meant that I received the replacement today. All I had to do was fit it, with low melt solder this time, to the spike on the bonnet front. It looks nice now...

Disaster 2

Things were going well. All the bits were on the model, a coat of primer hadn't shown up anything untoward so I mixed up a weathered black/black cup of paint to put the colour on.

Approaching the end of the job, all looked OK and I spotted that there was a corner behind an air cylinder still had a little primer showing through. I aimed the airbrush at it and a big drip of paint fell out of the cup - on to the model.

Trying to remove the blob, which had by then run down the side, just made things worse. I spraying more paint on the are but it just looked terrible. There was only one thing for it, the paint had to be stripped and done again. Quick work with paint stripper got the worst of it off. I just hope I can get in all the nooks and crannies so the new primer coat looks tidy.

If only people only looked at it via the pictures on the web, the problem doesn't show there !

Bonnet front with solder

The new version was interesting to compare with the one I sent off. The result is very clean and neat. Some shrinkage has occurred but not much - the width is the same but I think we lost a very tiny amount off the height and depth. Not enough to matter and once soldered in place and cleaned up the result looks good.

This allowed the radiator and funny metal thing in front to go on and make the face of the locomotive look finished.

Wednesday, September 03, 2008

Finished chassis

The white metal sandboxes and reservoirs were soldered on with the magic C&L 100 degree solder. A coat of primer was followed by Precision "Weathered black" brushed on. I prefer the thicker coat this gives and anyway I couldn't be bothered to set the airbrush up at the time.

This was all left to harden overnight and the mechanical bits were put back on. That gearbox works a treat as this is one of my most free running chassis ever. Wheels and cranks whirl round with no sign of tight spots or binding. I suppose that I had to get one right eventually !

Great Gearbox

This is a top 'box. I know it looks very simple but this is one of the best I have built in a loooong while. And that is a lot of model railway gearboxes.

Why is it so good ?

Well, first the etch folds up properly. The designer has worked out that at the corners you need to work out what overlaps what. A half etch rebate allows the construction of a square corner rather than the "fun" of trying to force two bits of metal into the same place.

The axles holes needed quite a bit of reaming to accept the bushes but far better that way than trying to etch holes the right size and ending up with something oversize.

Best of all though, the motor can go in with the worm gear fitted and the holes for the mounting screws can be used without alteration. A little allowance has been left to move the motor up and down to achieve the perfect mesh. In the last few boxes I've built these holes and the one of the motor shaft have had to be enlarged in all directions just to get the teeth together.

As this is for the 7mm Barclay, the whole arrangement is wide enough that the motor screws are either side of the worm so you can remove it while still in the frames.

Other gearbox designers take note !

Update: Apparently this 'box was designed on a napkin in a restaurant years ago when those concerned were slightly drunk. Other gearbox designers please note !

Monday, September 01, 2008

Tinternet comes up trumps

Sometimes you get lucky. A thread on Model Boat Mayhem forum about HFM boat kits lead me to a link on the Westbourne Models web site which showed a boat very similar to the Pilot boat I'm building. According to the description is is a Nelson 40 pilot.

Sometimes you get lucky. A thread on Model Boat Mayhem forum about HFM boat kits lead me to a link on the Westbourne Models web site which showed a boat very similar to the Pilot boat I'm building. According to the description is is a Nelson 40 pilot.Off I headed to Google with the phrase "nelson 40 boat" which threw up a load of results including some useful pictures.

A very similar boat is far sale here.

This one has been sold.

Valonia looks pretty similar too.

There are a whole load of Nelson Pilot boats here.

The photo of the factory looks quite a lot like my workbench:

There's a nice 45 footer for sale.

And this looks very similar to what I'm building too.

Finally - here is the manufacturer, Nelson Boats !

What I tend to do with all this information is grab the photos from the web (right click on them and select "Copy") and paste them onto a page in a DTP package (Word would work nearly as well). This give me pages of photos which can then be printed out for use at the workbench.

None of the pictures show the exact boat I'm building but there will be enough common features for me to use them when I need to answer questions about details that aren't shown in the images supplied with the kit.

Propshafts

This is my first model boat with twin props. Since the plans supplied with the kit are basic, and I can't find any more information out about the prototype, their location involves a little guesswork. I know how far back they go but the position across the hull has been done by eye. Lots of drawing on the plastic with a CD marker pen and peering along the boat until I was sort of happy got this right - I think (hope !).

The shafts are a pair of very nice stainless steal items which incorporate some phosphor bronze bearings in the ends. I forced some plastic tube over the ends and used this to give me something to attach the supports to.

The holes in the hull ended up being longer than expected. I wanted to keep the angle they went in as shallow as possible - as it is the line up with the motors is pretty close to spot on so at least something worked !

Filling the hull holes took three goes with Alteria plastic filler. There may be another splodge to go in once the paint goes on to get a perfect finish but at present it looks OK. Multiple coats were required because being a cellulose filler, it shrinks slightly when it dries and I was trying to use as little as possible to make tidying up easier.