A daily updated blog typed by someone with painty hands, oil under his fingernails and the smell of solder in his nostrils who likes making all sort of models and miniatures. And fixing things.

Sunday, December 31, 2006

Little boxes

Fortunately good gearboxes are reasonably cheap and easy to come by. This one is from High Level models with Mashima motor hanging off the back. Although it looks like a fearsome beast it goes together very easily. The toughest part is reaming out the holes for the intermediate shafts. These need to be done slowly so there isn’t any slop. Not a problem for most people but I have to stop myself taking too much material out - clean the hole, check, clean some more and check again. Little and often.

The shafts are supposed to be cut with a slitting disk in the mini drill. I prefer to use some big (Zebra) wire cutters as they don’t heat the metal up like the friction created by the disk does. The cutters have done no end of shafts, including the ones on motors, which are especially hard, and survived although I could really do with a new pair after 15 years !

One good thing about these ‘boxes is that they don’t require total precision. There is lee-way in the gears so perfect meshing isn’t required. Since I can’t mesh gears for toffee this is a relief. In fact my inability with gear meshing is the reason I started putting gearboxes in models in the first place.

Thursday, December 28, 2006

Death to Railway Modellers

This isn’t because it’s a terrible magazine – although it’s not as good as it used to be as there are too many layout articles and not enough on making things – it’s because I need the space. The shelf where the 18 or so years sit is full and other books and magazines are building up elsewhere. In the end the RM’s are the publication I need least.

So, I am busy reducing the pile. Plans and anything that looks like it could be interesting stay, everything else goes to the recycling centre. You are looking at about eight years worth of surviving text here. It doesn’t even fill half a box file.

Wednesday, December 27, 2006

Armstrong Chassis

Having messed around with the original K’s chassis, I’ve no idea how this was supposed to work. One problem is that the rear axle will, if the kit is built as intended, go straight through the footplate floor. At least it would if the axles weren’t several millimetres below the outside frames instead of poking through the holes they are supposed to.

My method for working this out was to solder two thicknesses of nickel silver together, mark the axle positions and then chop away until the part fits in the body. For no partially good reason I started with frames 15mm deep which were then reduced in places as required. Obviously you can’t go too thin as mechanical strength would be lot and anyway, the frame bushes need a couple of mm around them or you can’t solder them in place ! Once I was happy the sides were unsoldered and cleaned up to give to identical pieces.

Frame spacers are from Comet. I didn’t fancy trying to cut really accurate ones from raw metal when perfectly acceptable versions are available etched. No point in making any job harder than it already is !

Tuesday, December 26, 2006

Boiler battles

K’s didn’t do me any favours with the boiler on this loco. At least an hour has been devoted to scraping, filing and polishing the part into something that resembles round while keeping the boiler bands and sundry detail. The alignment was out by about half a boiler band. Not much, but enough to ruin a model if not corrected.

Most of the work was carried out with a three-sided scraper. I’ve never been averse to using a file despite the warnings of doom normally associated with this. The lead-based alloy will clog the teeth of a file, although using a course one helps, but these can be cleaned out simply enough using a file card or wire brush.

The body has now been tacked together using low-melt solder so I can work out the chassis. I’m not planning to use the horrible K’s item but it’s not obvious what shape works best. Tacking the item together means I can fiddle around and experiment. And if there is a problem or it all falls apart then I’ve not wasted too much effort.

Monday, December 25, 2006

Merry Crimbo

Santa really does work hard !

Saturday, December 23, 2006

Flash - aaarhh !

It’s also a right pain in the backside. You forget how bad mouldings used to be a couple of decades ago. We used to think this sort of thing was normal. Now the quality of castings has improved immeasurably. Even the guy doing it in his shed as part of a cottage industry is better.

Ideally I’d send these back but since the firm went out of business years ago that isn’t going to work. Of course as a “real man” I just set to and sculpt the bits to look right. Luck is on my side as the lime of flash doesn’t run across any detail. Even if it did, on the tender toolbox I could replace it with microstrip.

The boiler on the other hand, now that is proving more of a handful.

Friday, December 22, 2006

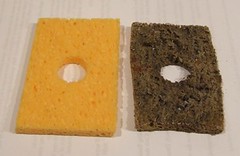

Sponges

What a poor, tired thing the old sponge was. At about a third the thickness and full of solder it really wasn’t doing its job.

Proper modellers clean the tip of their iron every time they make a joint. I probably do this every third or fourth joint. A clean iron makes better joins, it’s that simple. Back in the old days people would file excess solder and that weird black muck off the end of the iron. This also removes the plating and dramatically shortens the life of the bit. File too hard and it dramatically reduces the length and shape of the bit as well.

The old sponge has been in use for at least five years. I wonder if the new one will last as long ?

Thursday, December 21, 2006

Fame again

Lots of pictures of the inside, as that is where all the action is. For a cheap kits, and at under a tenner they don’t get much cheaper, there is a lot of fun in this little model.

Buy the magazine to read over the festive period. Then send the editor a letter demanding more from the same excellent author !

Wednesday, December 20, 2006

Fun and games with rails

First attempt – Use the supplied etched ones. These have to be bent to go around the corners and then the uprights are curved to fit the tender flair. I tined the bits to be soldered to the whitemetal with normal solder so the whitemetal version would stick. Nothing seemed to work. One of the uprights on each side got in the way of the divider at the back of the coal space. I fiddled away for an hour or so and pulled them off in frustration. They didn’t look much like the version on the prototype anyway.

Second attempt – Marking the positions using a plan, I made some uprights using 0.45mm wire. I then ran wire around for the rails. All soldering was carried out with low-melt solder. It sort of worked except at the front ends where I couldn’t get the curves right. The horizontals weren’t great either as they could be a bit lumpy where the solder ran along them. The joints were also weak but I couldn’t use proper solder as it would melt the sides.

Third attempt – After leaving things for a night and coming back fresh, I straightened out the etched rails and re-tinned them. Looking at the plan one upright does coincide with the back of the coal space so I clipped off the let that gets in the way. The mid point was marked and the corners bent so the rails were the right shape rather than trying to form and fit.

The end result is pretty good. I’m still not entirely happy that they are flat rather than round in profile, but what I have looks neat and tidy which is more important. When replacing parts in a kit it’s important that the replacement doesn’t look worse than the original – or there’s not much point in making the change.

Tuesday, December 19, 2006

Start at the back

The K’s kit has a very nice exploded diagram to follow and some instructions I didn’t bother to read properly. A good picture is worth a thousand words and this is certainly a good picture.

So far everything has gone together OK. Assembly is carried out with low melt solder. I know people are often scared of this having been warned not to turn the precious parts into a molten lump. In reality this is difficult to do as the solder has a lower melting point than the kit. Simply set the temperature of the iron hot enough for one but too cold for the other. Do not attempt this without an iron you can’t control.

All the parts have been assembled as supplied except the side frames which needed to be thinned down and moved out slightly. The kit is designed for OO and this will be an EM gauge model so I needed to squeeze a bit more room or the wheels wouldn’t rotate – not a feature anyone wants in a model locomotive.

Monday, December 18, 2006

Another one for the stockbox

With the chassis finished I reattached the body and started weathering. Since reading “The Art of Weathering” I have airbrushed a gentle weak mix of browns & greys over locos to take the edge off all the colours and provide the look of general grime that covers everything railway – at least in the bits I model anyway.

The trick from the book is to dirty the model and then clean it using a cotton bud dipped in turps. This simulates the efforts of the driver to keep his locomotive presentable. I had given quite a good coat so the cleaning really stood out. This was helped by painting the green bits in satin varnish so they stood out against the matt dirt.

Of course nothing stays clean forever and so another light coat of grime is applied. This means the “uncleaned” areas get even muckier and those that were wiped down don’t shine quite so much. Dirt clings in hard to reach crevasses exactly as it does on the real thing.

Whatever the science, the results look good, to me anyway. A little dry brushing on step edges and at the front where ash would be pulled out of the firebox finished the job.

All I had to do then was add coal in the bunkers, put the crew in place and clean the wheels.

Then I have another one for the stockbox.

Sunday, December 17, 2006

Chassis done

I usually just dry-brush some tank grey (Humbrol 67) on anything black and then add in track colour and rust where required. The important thing is to hide any pure black and highlight any detail. If you put rivets on anything, they need highlighting or no one will see them.

Dry brush work also gives a bit of the texture that real dirt has. We don’t want to go mad with this as this is real dirt scaled down 76 times – for all intents and purposes this means smooth. A bit of grain bounces the light around though, which looks authentic.

The last job is to go for it with some weathering powders. I’m not a huge fan of these as they don’t stand up to handling. In the inaccessible areas this isn’t a problem, and there is little better for simulating really think rust as found on the bottom of fireboxes and fronts of cylinders.

Friday, December 15, 2006

Putting the brakes on

Construction is very cleverly planned with all parts being easy to assemble. The shoes are three layers of etch and slot into the hanger. A small piece of wire hooks into the chassis so you don’t even have those annoying wires running all the way through and getting in the way. There is certainly no chance of clobbering the coupling rods with this method. In theory you can build the brakes and paint them before attaching to the model. You shouldn’t even need to solder anything to the chassis – I wouldn’t fancy risking this but others might.

Needles to say I managed to screw things up. Making the last brake assembly it pinged off into the distance, never to be found again. I paused for a while (several days) while thinking about the solution. In the end I just used two shoes instead of four. Since the loco isn’t really supposed to appear on the Hellingly Hospital Railway anyway, I think a bit of modellers licence can be applied here.

The rest of the bits fitted well filling up the back of the chassis. That little bit of detail puts some much-needed life into this part of the model. I like to see a bit of complexity below the footplate or it all looks a bit plain. Once upon a time this was how model railway were but nowadays we expect better.

All of this coincided with me dropping the chassis and bending everything behind the gearbox quite a lot. A bit of desoldering the frame spacer and bending the sides cured this but I don’t advise try it !

Wednesday, December 13, 2006

McDonalds, the model makers friend part 2

This time there is something for the painters – small wax paper pots. Each is 3.5cm wide and 2.5cm deep. To be honest I don’t know what you are supposed to use them for so can only guess they are provided for mixing small amounts of model paint it. They might also come in handy for holding small chassis parts such as screws while you dismantle things.

Now I am sure that Ronald M doesn’t want modellers around the world helping themselves to all his pots and stirring sticks but I say he can get stuffed. Let us band together and with a concentrated effort, bring this king of capitalism crashing down by our excessive collection of freebies. We will make the world of commerce quake at the threat of direct action. The Financial Times will be replaced with British Railway Modelling as the read of choice for the city trader.

Come to think of it, red curly wig might be OK if it were dyed and used for scenics…

Sunday, December 10, 2006

Why don't kits come complete ?

Most newbies wonder why model locomotive kits aren’t supplied with all the parts needed to complete them. It is a bit of a shock to look at the price of a box of bits only to realise that you have to add another chunk of cash, sometimes doubling the final bill, if you want to finish and run the model.

Some kitmakers provide beginners kits that are complete, others give you wheels or gearboxes as they manufacture their own and want you to use them. Most don’t bother leaving the poor modeller to work out what else is required. In the popular scales they usually help with a list but get off the beaten track (e.g. to 3mm scale) and you are on your own.

Now I don’t care. Having built more locos than is good for me, I have my favourite wheels, motors and gearboxes. When I buy a model I know roughly how much to add and where to get the extra parts. For the record, my favourites are: Romford wheels, Mashima Can motors & High Level or Branchlines gearboxes depending on the model.

Of course the beginner knows nothing of this. He or she wants it all in a box and wants to know why the model railway world has grown up in this apparently user-unfriendly way.

The reason is simple. It might at first glance appear to make things difficult but actually makes life easier. The Armstrong is to be built to EM gauge – so I need EM wheels. There are OO ones in the kit and they will be left over at the end. There’s nothing I can do about this. Motors and gearboxes are similar. If this kit had included one, it would have been a K’s one-piece unit. Fine if you like the smoke effects produced when this gives up the ghost but I prefer to put a good unit in first time so the loco is only assembled once.

Complete kits have to be built down to a price. This means you get cheap parts and not necessarily good ones. Worse, if you want to change something then you still have to pay for the part you don’t want and then replace it with the one you do.

In theory the model shop fills in the gap. New modellers want to buy a kit and the experienced man behind the counter offers sensible advice based on years of experience to help with the extra parts. Of course there are very few model shops and even fewer that supply locomotive kits. Mail order and chasing the cheapest price have seen to this. Manufacturers now have to fill in the gaps – fine most of the time but they often don’t stock all the parts themselves so you don’t have the one-stop solution.

I suppose this is all part of the learning curve for a modeller contemplating building their first locomotive. It is certainly a good reason for joining a club so you can learn from others mistakes.

Friday, December 08, 2006

Lines

As you can see the results aren’t half bad. The trick is to accept that the professionals don’t get it perfect first time and fill in corners or erase mistakes with a small brush.

I used the pen with Precision lining yellow and a bit of care. Only the straight lines were pen’d. I did the best I could to keep them straight and in line with the nearest edge on the bodywork. Once they were in I filled the corners with yellow to allow for the curve using my only pure sable brush. Finally the green was used to make the curves and fix my lining wobbles.

Last job was to spray the whole lot with satin varnish. Not to protect anything, just to bring the mat colours alive a bit. The result is too shinny and looks a bit toy-like but I hope that a good heavy weathering will calm everything down.

The lining pen was reasonably easy to use. It comes with only one size of nib but you can buy others. It’s not as flexible as a bow pen because you are very limited to the size of line. I know you can rule an extra line beside the first but that second one will be difficult to keep in line and neat. The secret is to make proper plasticard guides. For the IOM locos this will be on the “to do” list.

Wednesday, December 06, 2006

A Bit dead

Looking on the positive side, the iron (50W Antex) didn’t come to any harm. The same can’t be said for the bit though. No amount of cleaning and re-tinning would save it.

I’ve probably done my bit for global warming as well. At least I didn’t set fire to the house !

Still, after all the service this bit has done, all the kits it has seen and the fact I tend to use whitemetal and normal solder without cleaning it properly I suppose it was overdue for retirement.

Actually, the new bit worked a lot better than the old one. Perhaps there is a lesson in this ?

Tuesday, December 05, 2006

Manx Chassis

The Isle of Man Peacock chassis is finished. Not completely, there is still brake gear to add, but enough for me to be happy I can build these things and make them work.

This is a pretty fiddly build. Not that this is the fault of the kitmaker, Beyer Peacock have to take the blame. If only they had used a more conventional design. Everything assembles OK as long as you take care to open slots a little or file cusp away. Nothing too challenging although perhaps off-putting for the beginner. If you’ve done a couple of etched kits and take your time then this is do-able.

One point to watch is the front pony, which is fiddly to hold while keeping everything square. The bearings need to be pushed in a bit to grip the axle properly and this is the first time I have preferred top hat to waisted.

Anyway it’s back in the box now. Once day I’ll get around to building the body to go with it.

Sunday, December 03, 2006

(Not) Planning ahead

Today I decided to get out the Armstrong locomotive kit I promised top build for George.

Then I discovered that the box didn’t contain the motor, wheels or gears required to complete the model. Guess who now has to order all the bits he could have bought over the counter 24 hours ago…

The Armstrong will be an interesting project. I’ve always considered anything Great Western to be beneath me. Lets face it, GWR modellers aren’t really all there are they ? Lots of bucolic branch lines and pannier tanks but no proper engines. They take themselves soooo seriously too – some of us still remember the fuss they made when “City of Truro” was painted BR black for an April Fool years ago.

Perhaps I am jaundiced from the early years of my railway modelling life when every second layout was a GWR branch, probably Ashburton, so exhibitions all looked the same. I wanted something different which probably explains my love of little industrial engines. Preferably grimy, ugly ones.

Anyway, George seems to have a knack of picking the good ‘uns. This loco has the outside frames and elegant lines of a true thoroughbred. It has style and beauty and class. This is going to be a good looking model.

A problem solved

Anyway, I have the chassis trundling up and down a bit of GEM flexitrack (I think that’s what it is – it looks older than me) and decide to fit the rods and cross heads. The model continues to work but not awfully well. It’s a bit hesitant at some parts of the wheel revolution. I put this down to stiffness, iffy pick-ups or dodgy quartering. Things do seem to improve a bit as the model runs.

Then I spot the obvious. The rods are touching the wires to support the brake hangers. Not enough to jam things solid – I have been there before – but enough to make the wheel pause as it rotates.

There is no need to have the wires that long. On the finished model they need not reach as far as the face of the wheel but it is convenient to leave them longer than required while building as it saves measuring things.

Of course I have now chopped the wire back as the photo shows and the chassis runs a lot better for it. Perhaps by adding this to the blog I’ll remember next time !

Saturday, December 02, 2006

Warley & the demise of the hobby.

As you can see there is hardly anyone in the hall. Look at the empty gangways and the tumbleweed rolling through the venue.

This is obviously a hobby that is, as we are often told by wise letter writers, in it’s death throws. No one is taking part. The people who are interested are dying off. Strangely I remember that this has always been said. The attendees at exhibitions have always been middle aged and older men. Presumably they have dies off and been replaced by other middle aged and older men. I wonder if this is a pattern.

The show itself is excellent. I wouldn’t say it is the best in the world – something this big simply can’t guarantee that every layout and every trader is the best possible in the hobby. What you get is quantity. Hopefully there is something for everyone and most people will see something they haven’t seen before. On this basis you should leave happy.

I managed to spend money as expected. I was also very good and resisted some of the goodies on offer. If you bought an Impetus kit for a 4mm scale Fowler diesel then than me for leaving it there even though I really wanted to bring it home to my “pending” pile. Yet again I didn’t buy a Russian locomotive kit either. Or any Garrets (Ok, I’ve sort of ordered one but it is from a friend of a friend). Or anything for the garden railway (nice boxy loco kits from GRS for only £150, tempting). I couldn’t get to the Squires stand to buy a new tapered reamer either because of the crowds.

In fact there were only two downsides. First I had to come away at 3pm although the NEC is pretty tiring (not that I came back from the pub last night late) and the idiot who barged past me violently while I was queuing at a stand. Note to idiots: if you say, “Excuse me” people will often get out of the way. Otherwise you are obviously the sort of sad act with not interpersonal skills the media loves to portray railway modellers as. And that goes for you Mr Exceptionally smelly at the Bachmann stand as well.

If you are reading this on Saturday night you still have Sunday to get down to the NEC. Do it, you won’t be disappointed.

Friday, December 01, 2006

Running - sort of

It looks like I can build an IOM loco chassis and get it running without too much pain. Good news as the new layout isn’t really viable without them and I can’t see Hornby coming to my rescue any time soon.

Obviously there is supposed to be a front bogie to keep the nose out of the sleepers – I’ve built this but need another half hour to fit it. Instead a big nut on the back balances things out.

Quartering was “fun” as the jig wouldn’t fit the front ‘cos the running boards get in the way. The back was OK though so I set this and adjusted the fronts. Getting the rods over the fat Gibson bushes was interesting too. Not much metal left at the end of those rods.

However it looks like it works and so tomorrow I plan to spend some money with Mr Branchlines.

Wednesday, November 29, 2006

Beaten

This job has beaten me though. As I dig I find some solid metal and some rusty stuff. I think most of the rust is out but can see some at the ends of a box section.

Trouble is I can’t get the stuff out. The grinder is too big to cut away without removing loads of good metal to create access. I’m really feeling out of my depth here.

So, much as it pains me to do it, I have accept defeat and hand the job over to a professional with a plasma cutter and the experience to do a good, structurally sound job. Having looked at the job he’s complimented me on stopping when I did and agrees that if I were to start welding I would be trapping rust that would appear in time. I’ve also saved him time, and therefore me money, with the work I’ve done so far.

I suppose this is success of sorts but it doesn’t feel like it at present, especially as the van can’t go in for repair until Christmas. In the meantime Ashley sits on the drive making me feel guilty for not being up to the job.

Monday, November 27, 2006

Off to the Isle of Man (I wish)

Let me tell you a secret. The next layout my father and I build will be based on the Isle of Man. OK if you’ve talked to us at shows this isn’t going to be a huge surprise. Even if it is, I doubt it is as exciting as the story of Elvis being found on the moon or something.

If you model the Isle of Man (hereafter called IOM to save my fingers) and doing the steam railway, you build Peacocks. Loads of ‘em.

With Warley show at the NEC this weekend I’m going to be adding to the stock of IOM loco kits currently maturing the in the cupboard. It seemed prudent though to see if they were any good before trying to persuade Branchlines to do a deal for another eleven. (Note to self: This is a joke. You will only be buying one kit this time). Digging the kit out of the box labelled "IOM” I find that the wheels are Gibson and not the normal (and preferred to be honest) Romfords. Since the next big project will have Gibson wheels, albeit with EM axles, I might was well get the practise in.

IOM Peacock chassis are complicated beasts. There is a lot on show and what you see give the locomotive most of its character. The Branchlines kit was designed in the 1990’s and was one pretty state of the art then. It’s good today as well. Etched in nickel silver, a lot of thought has gone into its design. So much that I had to follow the instructions to the letter to get this far. What you see is just under two hours work and I still have work to do, notably on the prominent front pony.

It all looks fine so far. As long as it if flat and square I should pretty quickly have a running chassis. Then I get to decide how many more to add to the collection this weekend.

Saturday, November 25, 2006

Petrol tank - In

I poked wire through all the holes to make sure they were clear. Cleaned out the outlet with a drill as it was very full of hard tank paint and then slid the tank back into place.

Obviously there was a bit of pushing and shoving involved but nothing major. The wires to the reversing light need replacing as they got in to way once too often but apart from that everything went fine.

There is extra rubber between tank and tank hole (what else do you call it ?) which I slid in before tightening the retaining straps. The threads on these had to be cleaned up with the die (8 by 125 I think) and as usually every bolt has been greased to build my stock of karma up.

With the firewall in place again the job is nearly done. In theory I could have the engine put back in and drive off into the sunset.

With the lump out of the way though it’s time to tidy up the engine bay. I’ve scraped and re-painted a fair bit already but there is another horror awaiting me. The rear valance is well rotten. With access as good as it will ever be I can’t put off tacking this any longer.

Thursday, November 23, 2006

It's raining lead

Some weight is important and etched brass locomotives definitely need a bit of help. The mineral engine doesn’t offer much scope for lead though – the boiler is pretty much full of motor, gearbox & flywheel.

Fortunately the bulges in the saddle tank are hollow and have holes obviously intended to give access for weight addition. Just the job for some of that “liquid lead” I bought a long while ago and have hardly used I thought.

Pouring it in was out of the question but a small plastic spoon, the sort you get with ice creams in tubs, shovelled it in and some superglue poured on top should have solidified it.

I needed more glue as it turned out. Running in was interrupted by stopping to pull squashed lead balls out of the gearbox. I think I dismantled the model half a dozen times before giving in and pouring more glue into the hole. Even now the odd ball escapes but I’m hoping all the loose ones will soon fall out. I want the ratio of brass to superglue to stay about the same as it is now and not tip in favour of the adhesive.

Wednesday, November 22, 2006

Tap and tank

Sitting in the sofa and eating chocolate since you ask but I want the van back on the road so it’s into the garage.

All my painting had closed up the holes the sender bolts in to. After careful measurement and a lot of squinting at the top of the bolts the number 8 tap looked like it should clear out the threads. Before I could do this, the holes had to be opened out with a 3.5mm drill.

With everything cleaned up, the sender was bolted back in. It’s rubber seal didn’t seem to line up with the bolt holes very well but was flexible enough to allow some prodding to get things together. All the bolts were greased of course before they went in as I’m hoping the karma will spread and I won’t have to undo too many of their rusty cousins in the future !

Sunday, November 19, 2006

Lovely day

Minty’s new coupling worked well. She has a nice turn of speed, reasonably fast but no scary. You don’t have to concentrate too hard to avoid the bank or other craft. Good thing too as the pair of dogs living on the site decided that we had nothing better to do than kick their football.

The duration of run is very impressive. I sailed pretty solidly for 30 minutes and there was more in the tank (battery). I suspect that another 10-15 mins wouldn’t be out of the question. This makes the boat ideal for regatta days when the water is busy. Since our lake is on the small side half a dozen boats mean “near-misses” are common.

At the end of the day I have built what I wanted. A model that can be quickly charged and taken out for a pleasant sail if the weather looks good. No fuss or setting up, just enjoyable sailing.

Saturday, November 18, 2006

Welding lessons

Still, with this practise under my belt I moved on to patching the holes under the petrol tank. In theory these would be reasonably easy (read: doable by a newbie welder) but to be on the safe side I made a trial piece up out of a couple of off-cuts. One reasonably successful lap joint later I decided to be bold and try it for real.

First I cut the patches from 0.8mm thick steel. They seemed to fit OK. Next I cleaned the area to be welded again with the angle grinder. I’m smart enough after years of soldering to know that you need clean metal and it’s not clever to struggle with anything else.

Then I took the welder for its first trip outside. The ensuing struggle lasted about an hour I think (don’t wear a watch while doing this sort of thing, a lesson learned a long while and several watches ago) but resulted in two bits of metal attached over the holes. Fortunately they aren’t structural although most of the welds aren’t bad and some of them are very good.

What I learned today is:

Use the red welding visor. It doesn’t have a flip up lens like the black one but what it does have isn’t so dark. I can actually see what I am doing but not get dazzled.

Welding visors protect your head when you keep hitting it on the engine bay roof.

The engine bay roof is in the way.

If you kneel on the lead to the welding torch the wire won’t feed through.

You can’t tell that you are kneeling on the cable when wearing kneepads.

Other than this, kneepads are good. I must buy a better pair that the ones from the 99p shop I’m using.

Getting a good earth on a vehicle isn’t as easy as you think.

Welding isn’t affected by failing light as much as other activities.

Seam sealer is difficult to get off your fingers.

I love my new metal cutting tool. Except when I catch my fingers in the handles.

A small hammer is good for persuading metal into shape. You don’t always need the “proper” tool. Brute force can work. Sometimes.

I would like a proper indoor garage. And a vehicle lift.

Friday, November 17, 2006

Gluey lesson

If the parts are a stand for a model boat then you end up dropping the model and breaking bits off.

The flagpole went back on without any problem. The top of the searchlight will be more of a problem.

The stand has been re-assembled with 2 part epoxy. It won’t come apart now !

*It said it was painted, but the paint feels like plastic.

Wednesday, November 15, 2006

New coupling

“Little Miss Minty”’s biggest problem was the coupling between the motor and propshaft. I had used molybdenum tube but this kept failing. It looked like that I’d need to do major surgery to get a conventional coupling to fit – they were all too long for the space available.

At the boat show when I wasn’t buying new kits (yes more projects, but I only go to one big boat show a year so I have to stock up OK !?) I took a look at the Deans Marine stand where they had several couplings. These look like they are modular and the smallest version looked promising. At seven quid it wasn’t a cheap bet but I though I could always use it on something else if needed.

An initial check showed things looked promising. All I had to do was release the motor from its mount with a bit of screwdriver fiddling. The access wasn’t easy but I managed by using a combination of tools. If I had planned better perhaps I’d get a straight run at the screw heads but then I don’t intend taking the motor out much.

The couplings input & output shafts were 2.6mm. This is fine for the motor but my enlarged propshaft was too big. A few minutes with drill and reamer cured this giving me a nice snug fit. Happy I reassembled everything.

Once I’d done this I rotated the prop and noticed it caught on the hull. A quick look showed it had moved backward by about 4mm. The problem was that the propshaft was as far into the coupling as possible and it wasn’t enough. I did ponder living with it but gave in and took everything to bits again.

A big fat pair of wire cutters dealt with the excess shaft with a bit of a struggle but they did it. I then put it all back together. Result a nice free running propeller which under power is quiet and therefore efficient. I haven’t had a chance to try the boat on the water but hopefully (fingers crossed) this won’t result in another drive failure in the middle of the pond.

Tuesday, November 14, 2006

Tolworth Part 2

In this case the surprise was in the form of a couple of brick remnants in a plastic bag and some bad news. It seems that the most important surviving survivor of the Hellingly Hospital railway, the engine shed, has been burnt down by vandals.

Until recently the shed had been in use by a garage as a workshop. It featured the original trolley wire in the roof and embedded rails outside the front doors. I had always dreamed of retrieving some or all of this for preservation. The idea of stringing some of the wire across the top of the model seemed good. Of course living 200 miles from the shed meant I couldn’t visit nearly often enough to try and arrange this.

Now the shed has gone but at least, thanks to the generosity of a visitor, I have a small part to display with my model railway. For the rest of the exhibition I merrily told the story and allowed others to examine my precious artefacts.

Coincidentally, my benefactor is a volunteer at the excellent Amberley Chalk Pits Museum. This is home to one of the engines from my favourite railway – The Groudle Glen Railway on the Isle of Man. We spent a good while chatting about this as well.

This sort of meeting makes getting up at 5:30 in the morning, driving half way down the country and standing on a very hard floor for eight hours a day.

Oh, and the answer to everyone who asks, “Do you have your layout set up at home ?” The answer is most definitely no. I just can’t enjoy operating without someone to talk to !

Sunday, November 12, 2006

Tolworth Part 1

It’s not a bad model railway exhibition as they go. There were plenty of layouts and certainly in the main hall and not a duff one to be seen. Some seriously impressive modelling was on show. If I’d been a visitor I would have felt I’d had my moneys worth. Since you get three halls for the price of one there really is something for everyone.

I was especially impressed with the American hall. The models in there were proper modelling with dirt and wear and nothing taken straight from the box. No cowboy hats to be seen either.

Trade was good too. Perhaps not the best in the world but no-one could complain about the selection of locomotive kits (in 4mm scale at least) with one kit manufacturer (Roxey) and a couple of stalls with good stocks of second hand kits. Despite my plans not to buy any more projects I have come back home with a couple. Of course they were kits I had planned to buy one day anyway, and they were a bargain…

The biggest downsides weren’t the organisers fault. The leisure centre owners have employed the slowest builders ever to refit their toilets. For two and a half months they have been messing around and still haven’t finished the job. This means a reasonable sized exhibition has to content itself with three loos. Two for men and one for women as the former made up the largest percentage of the crowd by far.

The other problem was the crowd itself. For the first half of Saturday they didn’t speak. At all. Absolute silence despite my best efforts to get some chat going. The first morning is always filled with enthusiasts and they never speak to the layout operators. Oh no we have to far too serious for that. With the Hosptial offering limited operational potential, we are as keen as possible to get to talk about it. There is history and model making techniques to discuss. Or you can just stand and look serious.

Fortunately the atmosphere improved after lunchtime on the first day when the normal people start to arrive and the serious people loosen up a bit. We managed a good few conversations and even some laughs. As we’d left home at 6:30am earlier we needed this to keep our spirits up. Early starts and 104 mile drives tend to take the shine off playing trains even in a good show.

Friday, November 10, 2006

Fame again

Best of all (from my point of view) is that on page 72 there is a two page article by ME describing my experiences with a Compass Models (marketed by Ripmax) Slingshot. Fame at least in the model boat world !

Thursday, November 09, 2006

Rust removed

The inside has now been treated with the fuel tank paint. I poured it all in as instructed, sloshed it around and then poured the remainder out. About three-quarters of a can came back out so I’ve put the lid back on and let everything dry.

Peering inside as best I can it looks like everything is painted a silver colour. Where the surface isn’t pitted it looks really good. The previously rusted areas have a rough surface but at least it is a silver painted rough surface. I plan to repeat the sloshing to use up more paint and give a better coverage inside. Better safe than sorry – I don’t want to pull the tank again !

The outside was rubbed down and painted with Smoothright satin grey. This is a bit light for real concours buffs but it’s near enough for me. The results look very nice – like a brand new tank. Hopefully with both inside and outside treated my tank will be better than new.

Tuesday, November 07, 2006

Off to Tolworth

We put the layout up quickly to make sure everything works. Apart from a couple of dry joints in the fiddle yard, everything does. The joints wouldn’t be a problem if I bonded around them with extra wires (the joins are in rails soldered together) but it’s not a job I ever get around to.

I took the chance to gather everything into the same room as well. Hopefully this reduces the chance of forgetting that vital lead or important tool.

There was even time to run the new locomotive. Of course it decided to play up. As far as I can tell some glue vapour has got into the gearbox. A bit of power forward and reverse seemed to cue things but some running in will be required. Just the thing to do in those quiet end of days bits of the show.

Sunday, November 05, 2006

Fiddly waggly bits

As I’ve found before, the design of this kit is superb. The cylinders fold up and are strengthen with some thin tube that the piston rods run in. The slide bars are etched and also fold. Holes are provided to line parts up. If there is a fault it’s that the cylinder wrappers are on the thick side and could do with annealing before you try and form them. I managed but would do things differently if I built another.

The crossheads are cast brass. Very clean too. You solder a brass piece to the back of each to finish them. This traps the rod so some tidy soldering is needed. I cheat a bit and coat anything I don’t want soldered with permanent pen. Solder hates dirt and this keeps it away from problem areas – mostly.

This whole arrangement is very fine. Although it is stronger than it appears I’ll still be glad once it’s firmly fixed to a locomotive.

Friday, November 03, 2006

McDonalds - the model makers friend

Anyway, I’ve seen these before and they are a useful part of my modelling toolkit.

The first option is to see them as a source of raw material. The wood is close grained and suprisingly good quality. By splitting the stick down the centre along its length you get two nice 4mm scale planks. After a light sand the results are great for loading wagons. There are a couple running around my hospital layout like this.

The second use is in holding bits of brass while soldering. Lolly sticks and wooden chip forks are also good for this. Once the bit of wood gets charred, chuck it away and use another. They last for a very long while. I often push one end of the stick against the board and stuff the brass bit under the other. This keeps my delicate pinkies safe from the nasty heat.

If you can’t face a trip to the golden arches, Weatherspoons pubs and some coffee shop chains also offer these so help yourself !

Tuesday, October 31, 2006

Cleaning out the tank

Well I have to disappoint you. Currently I’m still working on the fuel tank from my VW Camper van. So far I’ve taken it out of the vehicle and have been pouring treatments into it in an effort to remove all the muck in the bottom.

The first stage of the process involves “Marine Clean”, a high powered degreaser. It’s so powerful that the bottle in the picture has to be diluted 5:1 with water. The results on the tank contents appear impressive. On the first washing (half a bottle) a load of rust coloured muck poured out. The second gave more but not as much. A screwdriver scraped along the inside of the tank brings back no lumps of crud.

Now a regular task when kit-building is to clean the grease off a model before painting. I wonder if this stuff would be any good ? There is a little left in the bottle for me to find out, so where is that mineral engine kit ?

Sunday, October 29, 2006

Trial and error

To be fair I learned a lot. Having been on a proper course it is really time to put the lessons into practice. At the college the machine is pretty much set up for you. The material you play with is thick and you are only doing fairly simple joints.

I have to set my machine up and work on thin metal. Of course I’m not joining to bits, I want to try and build up my weld pool to fill a rust hole. This is like trying to ice a cake with molten metal. Not being able to see anything properly doesn’t help. I need a strong light so I can see the work piece through the welding mask – or I’ll continue to miss the bit I want to fill and blow a hole in something else.

After two and a half hours of messing around and frustration I thought I had it. My weld pools were getting better. I learned to use the green gloves not the red ones as they gave me better control over the trigger on the welder. I learned that the contact the earth makes with the metal is vital and can be disrupted by a bit of rust or dirt. I tried different settings and made holes when I shouldn’t have. I fiddled with the wire tension and speed. I heard the sound of a good weld crackle and the spit of a duff weld as well.

I had to give up through lack of light. Not inside on the bench but outside where I was grinding the welds flat. Through sheer laziness I hadn’t installed a light outside so when the daylight disappeared I was grinding in the dark. A lead lamp helped but only to make me over confident. So over confident I ground right though the metal I was welding back in.

I learned about grinding today.

Saturday, October 28, 2006

Petrol tank out

It’s not as big as I thought it would be. Not sure why, but I expected something at least twice this size. Stupid really as there isn’t the space for anything larger.

Anyway, apart from having to stop work to buy a deep 13mm socket to remove the retaining straps, everything went pretty well. The bolts and screws undid OK with only a little effort. Of course the tank has been out in the last eighteen months for a new fuel gauge sender to be fitted so this isn’t that much of a surprise – except to anyone who has ever worked on an old car and knows from painful (!) experience how fast a bolt can decide it wants to stick in a hole.

In the bottom of the tank is a nice thick layer of sludge made up of muck and rust. The top of the inside looks clean though. I’ve got some POR Marine clean soaking the sludge away at present. Two treatments each lasting 24 hours are proscribed on the side of the bottle so that’s what it gets. I only plan to do this job once so I will break the habit of a lifetime and do what I’m told by the labels.

I have found more rust to deal with in the tank compartment. Looks like I need to get aquainted with the welding kit to sort this out. The whole job is suffering mission creep as I add to the “to do” list all the time. I know this is what happens with old vehicles and I know that if I do a proper job I’ll be much happier. Doesn’t mean I wouldn’t love to have just one job go quicker and easier than expected.

Oh yes. My plans to re-paint the outside of the tank have stumbled as well. It’s dark grey (“Tank grey” to Humbrol paint fans…) not gloss black. Still, I’m sure I’ll find another use for the paint I bought !

Friday, October 27, 2006

Petrol tank treatment stage 1 - Engine out

Stage one is to get the engine out of the way. I’ve never done this myself so have had to pay to get the work done. Because I’m on good terms with the guy who does mechanicals (& welding) for me, I’ve had the engine dropped on the drive. This allows me to work on the petrol tank at my own pace.

Engine removal isn’t too painful. If I had a suitable trolley jack I’d be able to do it myself I’m sure but as I don’t, I can’t. I do get to help which is always interesting and educational.

For now I have a mid-engined van. Admittedly this isn’t going to give the performance and handling you normally expect from this sort of vehicle, what with it siting where the cooker is supposed to be and not actually attached to anything.

Tuesday, October 24, 2006

Armstrong Whitworth Diesel Shunter

This is the first finished model Armstrong Whitworth locomotive from the Mercian Models kit. Apparently she was called “Alice”.

Built and painted this is an impressive model. If I worked in 016.5 I would be sorely tempted. I know that there was (apparently) only one built but it looks like a very typical diesel shunter. At the head of a train of hoppers of other metal wagons the locomotives strong, purposeful shape would fit in fine.

Preserved railways often have something like this for shunting, works trains and when they can’t be bothered to steam a chuff chuff.

This isn’t a difficult kits to assemble. It’s etched in nickel silver – always a plus because it solders so much better than brass. There is a bit of forming to carry out on the bonnet but this isn’t too bad and can’t really be avoided on this sort of loco. Apart from the issue with the buffer holes (this is going to be fixed) then there isn’t anything wrong. There is plenty of space for a motor & gearbox. I would recommend a two stage unit as the model demands a very low top speed. Event with a flywheel fitted as well there would be loads of space for lead in that bonnet.

Best of all I’ve knocked off another of those projects from my list.

Monday, October 23, 2006

Fiddly Bits

This was a challenge but a good one. Each lost wax cast brass part has to be removed from its sprue, doing my cutters no good at all, and then drilled for the bits of wire to be attached to it. The instructions give different wire sizes but as they vary by less than .3mm I just used the .5mm wire for them all. Well except for the .3 stuff, which I ignore entirely.

One drilled, tinned brass wire is inserted into the indentation (I can’t call it a hole as the brass is too hard to drill very far) and lightly soldered. Suprisingly this works very well as long as plenty of flux is used. I cleaned the joins up a bit with a file but not much. Far harder was getting the wire in at the correct angle – I had to remake several joins as the pipe exited the fitting at an odd angle.

The results are everything a Victorian railway locomotive should be. Overly ornate with too much pipework on display. Lovely.

Sunday, October 22, 2006

Grot

Weathering is easy with an airbrush. Mix a weak rust/dark brown paint up and spray it lightly all over the body. Go over the lower areas a bit more to deapen the effect. Dry with a hair dryer and take a look to see if a bit more muck is in order. One happy, repeat with a dark grey/brown mix.

I experimented with holding the spray further away from the model than recommended. This allows the paint droplets to dry slightly before impact and imparts a fine texture – just like real dirt has – to the paint.

A little dry-brushing in selected areas and the body will be finished. Now I just need to do the same with the chassis.

Saturday, October 21, 2006

Little peg into a larger hole

This is why kits have to be test built by idiots like me. As you can see the hole that the buffer is supposed to fit into is quite a bit larger than the shank. Actually it’s nearly larger than the buffer base (the square bit) that is supposed to sit on the buffer beam of this model locomotive.

Now as I’ve had a bit of practise at model making I managed, with only a little swearing, to fit the part with low-melt solder. The solder acts as both adhesive and filler in this instance and the result is not too bad.

Now I have to tell Trevor he needs to alter the etch. Still better to do this now than on the production batch.

Update: I think I know how this happened. If you look at the front and rear views on the plan there are circles for the buffer heads. I suspect that the designer managed to etch these instead of the correct size versions. Easy done and easy fixed.

Thursday, October 19, 2006

Old Instructions

The current project has scared me. It is a High Level Models mineral locomotive. I bought the kit on the strength of the article on Hellingly Hospital appearing in British Railway Modelling. Most of the cheque was used to fund the kit, something I think is only fair. Since the layout earned the money I should spend it in the layout.

High Level kits are superb. The parts fit together nicely and the instructions are second to none. For such small models they are very complicated to assemble but the process has been thought through and as long as you do what you are told, all will be well.

To keep my place I have been jotting down dates and ticking off stages so I know where I am. This is at least the third time this model has been on the bench. I wasn’t prepared for the date found on the paper which indicated the last time I’d done any work – it’s over a year ago !

Well, progress has been made. The rear buffer beam and cab sheet have been attached. Perhaps I might get a working model before the box beckons again. My incentive is a show in a few weeks with the Hospital where I could run the loco. Maybe I can squeeze a bit of time out of this weekend…

Tuesday, October 17, 2006

Another one bites the dust

For months there has been a pair of On3 (I think; what we call O16.5) wagons built from kits awaiting couplings starring at me. I kept planning to get around to them but instead something got in the way. The wagons have had to be dusted a few times so they really would be better finished and in a box.

Last night I finally got on with it. The couplings fitted are Kadees which I was given by someone who fancied using them on his wartime layout and then decided they would be too much work. All I had to do was superglue them in the right spot under the buffer beam.

Kadees are notorious for being fiddly to fit. I think you are supposed to use gauges and stuff to get them right. I don’t have a gauge so I just checked they would couple with the loco (a Bachmann 0-4-2) and each other. Not sure if this will be good enough for curved track, but as they don’t have a layout nor any prospect of one in the near future, this isn’t going to worry me.

I was amazed at the engineering in such small and relatively cheap items. They are proper fully working knuckle couplings as fitted to American railways. Far more sophisticated than the traditional UK tension lock beast.

Monday, October 16, 2006

Fame at last !

In the November 2006 issue of Volkswagen Camper & Commercial magazine, page 37 features my replacement of the thermostat in Ashley. Top quality pictures, well written prose. I can’t praise it highly enough.

Buy your copy today !

Sunday, October 15, 2006

An audience with greatness

It is a beautiful example of the model engineers art. A part built Foden steam lorry on show at the Midlands Model Engineering Exhibition today. The chassis is superb. The woodwork for the body is absolutely amazing. It is cabinet making of the highest quality.

When I was a kid I always wondered why the model engineering section of the local festival was full of part built models that looked the same from one year to the next. There are only so many steam boilers you can look at before wanting to go back to the toy trains where things actually move. Why didn’t these guys get on with it and finish the models. It was explained to me that they took many years, often more years than I had been alive to complete, but it never sank in.

As a grown-up I can now appreciate the workmanship. To be honest the sight of a boiler without a machine around it still does nothing for me, but other objects are works of art. I have learned to appreciate workmanship for it’s own sake. Makes something properly and I can look in wonder.

The wood framing of the steam lorry amazes me. I don’t think I would ever be able to match the quality in my lifetime. But then I might also argue that as the frame will be covered when the model is complete, perhaps that fine finish isn’t really necessary ?

Of course the builder has gained enormous pleasure from the work and that alone justifies it. He probably looks at the doweled joints and smooth finish with that inner glow of satisfaction that you get from a job exceptionally well done. Doubtless the rest of the modelling will be carried out to the same high standard. I just hope I get to see the finished item. Sometimes bodgers like me need to come into contact with perfection to be inspired. Maybe next time I make something I’ll manage to raise my standards just a little.