Assembly of the Fantail launch's steam cylinder is pretty easy. The instructions recommend solder and seem to indicate that you need to use silver solder for best results. Re-reading though what they actually suggest is normal tin/lead solder but with solver in it. Nowadays it is easy to get lead-free solder and the best stuff has a small amount of silver in to make it "wet" more easily.

I did try silver solder but can't get the correct flux (it's on backorder) and the flux I have wouldn't make it run. So I used lead free solder with silver in it - and it all worked fine.

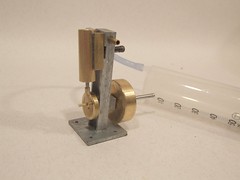

A small gas torch got things hot enough to fix the cylinder to it's block (the swively bit, not sure what the correct term is) and also make up the piston. Both were cleaned up and special effort made to make sure the piston moved freely, but not too freely, in the bore.

Once screwed together I tried testing by blowing in the ports but couldn't move the piston. Plugging a big syringe in did the job though. Compressing the air by about 2/3rds got the engine running for a couple of seconds until the plunger reached the end. A proper compressed air source would have been better but this did the job. And it was addictive - I must have spend half an hour just turning the engine over like this as I was so proud of getting this far and having it working.

No comments:

Post a Comment