Tension locks usually sprout from somewhere under the buffer beam. There are standards for height but I simply used a Bachmann wagon as my guide. Even if you follow the recommendations to the letter I don't think the job is done until you have tested with real live rolling stock anyway.

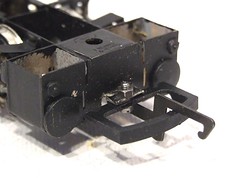

At the front, fixing is complicated by the chassis - it's in the way of the pivot. This is turned to my advantage by cutting a couple of slots and bending the spacer up to provide a fixing point. A 10BA bolt hold the coupling in place. I felt it was sensible to allow for the removal of the items should the owner wish to change over to something else in the future. Besides you don't want the glue joint giving up on this the moment you try and shunt a heavy train do you ?

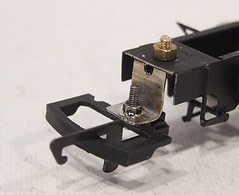

The back was actually trickier. While the chassis isn't in the way it also doesn't provide anything in the way of support. A small bracket that makes use of the body fixing screw does the job here. It will mostly be hidden by the buffer beam anyway so no one will nitice I drilled the top hole in the wrong place first time I hope. For clarity a brass nut stands in for the body and allows me to test things without risking my nice paintwork.

The back was actually trickier. While the chassis isn't in the way it also doesn't provide anything in the way of support. A small bracket that makes use of the body fixing screw does the job here. It will mostly be hidden by the buffer beam anyway so no one will nitice I drilled the top hole in the wrong place first time I hope. For clarity a brass nut stands in for the body and allows me to test things without risking my nice paintwork.The chassis now couples to my wagon and hauls it up and down the test track happily enough so it's time for the finishing touches.

No comments:

Post a Comment