Both tanks are now in place. Bending the tops was entertaining - I used a length of brass tube that seemed reasonably close as a former. That and some poking, prodding and bad language !

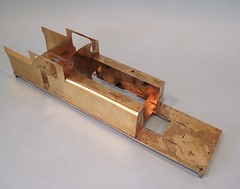

Both tanks are now in place. Bending the tops was entertaining - I used a length of brass tube that seemed reasonably close as a former. That and some poking, prodding and bad language !Actually, it wasn't too bad. The bend starts lower on the side than I initially expected but thanks to the half etched relieving lines the metal could be re-formed without any problems. I was careful to make sure that the top and side were are right angles to each other all the way along. Then when the second side went on I did the same but additionally checking that the two tops were level. Lots of tacking and testing there but hopefully it will all be worth it.

Inside there is an inner tank which includes supports for the boiler. Huge cutouts are included for the wheels - far larger than required in my opinion. I knocked the odd sharp corner off too as my soldering inside the tanks isn't perfect and removing the very tip of the corner lets the parts slide in easily.

No comments:

Post a Comment