Last Sundays' post

Last Sundays' post about a missing model railway concerned a model of a proposed channel tunnel scheme. This prompted Graham W to take the time to send me a scan of an article that appeared in the Eastern Region Magazine (all the regions of the real railway network published in house magazine, a process that originated from thier earliest days as separate companies) that described the very layout I was interested in !

Thanks to Graham I've managed to wear my fingers out on the keyboard and can bring you the following:

***********************************************

Channel Tunnel Terminal – model built in less than four monthsDescribed by A.W.AshberryUndoubtedly a magnificent model ! And it shows what the Model section of the BTC Publicity division can do. Three enthusiastic craftsmen from Stratford Loco works lent a hand.

Started at the end of June, it was required for demonstration at the Channel Tunnel Study Group's conference at BTC HQ in October. It was widely publicised on the radio, TV and in the national Press and will be shown at the Schoolboy's Exhibition at Olympia in London after Christmas.

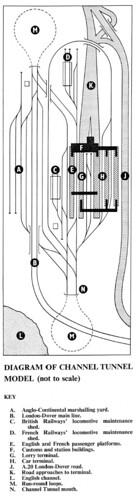

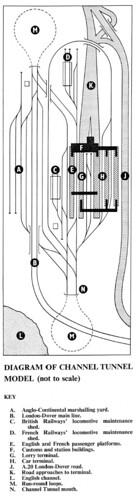

The 30ft. X 8ft. Working mode is of the railway terminal at the English end of the proposed Channel Tunnel and illustrates the principles of design and operation. It shows the essential features of a tunnel terminal but is necessarily simplified and reduced to a reasonable size for exhibition purposes. In practise the terminal will be three miles long and six miles from the tunnel mouth.

Built to scale, one seventy-fifth of full size, construction was undertaken at the Model section's workshop at Stratford Works (ER) in East London. Rolling stock and the miniature cars come from commercial sources.

Construction of baseboard and track

Construction of baseboard and trackThe baseboard is built in ten sections each 6ft. X 4ft. which bolt together. It can easily be dismantled for transport and is supported on tubular steel legs adjustable for height. The material used is 5/8in. blockboard.

The rails are of nickel silver soldered to metal plates set in fibre sleepers, enabling two-rail electrification system for model railways to be used throughout. By this method locomotives pick up their current from one rail and the return circuit is completed through the other.

Ultimately the tunnel itself will be electrified on the 25kV AC overhead system, whereas the Southern Region is electrified on the 750 volt AC third rail system. Dual voltage power units would therefore be used on through services.

Both these systems are represented on the model but only in dummy form. The pantographs are, however raised automatically and lowered as they approach or leave the overhead system.

The layout is completely signalled with multiple-aspect colour signals which, although working models are not at present wired up. If this were ever undertaken the relay room would be nearly full-size !

Buildings and scenery

The main buildings are constructed entirely from 3/32in. perspex sheet which when scribed for windows and painted provides a quick method of construction in contemporary style. The locomotive maintenance sheds and signal boxes are built from plastic kits. The scenery is built up on wood formers covered with 1/2in. chicken-run wire netting. This netting is then covered with muslin soaked in plaster which, when dry is given another coat of plaster and covered with impact adhesive. A fine coat of sand is sprinkled over the glue while tacky and finally the contours are hand painted with tempera colours.

A most attractive corner of the layout depicts a section of the white cliffs of Dover. A mixture of Scotch glue and sawdust was plastered over plywood formers and then covered in plaster. The cliffs were hand painted and the sea is a sheet of rippled glass over a painted underlay.

Rolling stock

There are five fine models of the Bo-Bo electric locomotives now in use on the Manchester-Crewe overhead lines resplendent in “electric blue”. Also one French model of the BB 16,000 class which hauls French trains on the Northern and Eastern lines. One 350hp diesel shunter works in the small marshalling yard. Eventually there will be a 4-car set of BR electric stock to work along the Dover-London line represented on the model. One train of French silver steel coaches and two trains of BR standard maroon coaches complete the passenger stock.

The varied freight stock includes perfect models of the new Roadrailer vehicles and Continental and British wagons. The accent is, of course on the double-decked car-carrying wagons. Although shown as open wagons on the model, in actual practise they will be covered.

There is also a train of single-deck wagons on which model cars are run under their own power – through an electrical pick-up. They are stopped on their respective rial vehicles and the train proceeds on its tunnel journey. A train returning from the “French side” with a similar load can be brought into the unloading dock where the cars are run off, again under their own power. This is accepted in the model-making world as a unique feature.

Congratulations are due to the designer, Mr Ron Beddoes, and builders of this fascinating model which will undoubtedly be well received wherever it is shown. This glimpse of the pattern proposed for future cross-channel transport will conjure but one thought in all viewers' minds - “How soon ?”

***********************************************

This is fascinating stuff. The article contains many fascinating points:

The track was hand built using an early form of PCB style construction rather than buying off the shelf items. Fibre sleepers are notorious for being affected by changes to the atmosphere so you wonder why they did this.

At 30 by 8, this model would well within the reach of most model railway clubs. Anyone fancy a reproduction as a project ? I wouldn't recomend the blockboard baseboards though if you don't have a club full of weight lifters !

The unique car system looks very similar to what eventually became the Minic-car system. I wonder if one influenced the other ?

But the big question still left is, what happened to this model ?

(Thanks to Graham for sending me this article)

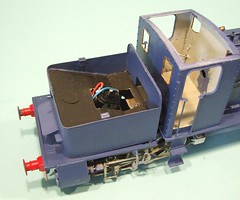

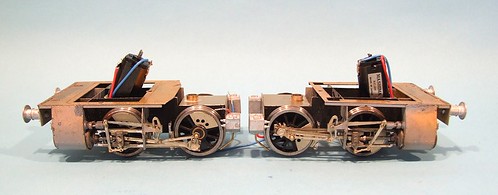

Happy days. I've stuck rivet strips all over the tank end of the Garratt locomotive. I did my best to follow the photo and the results don't look half bad.

Happy days. I've stuck rivet strips all over the tank end of the Garratt locomotive. I did my best to follow the photo and the results don't look half bad.