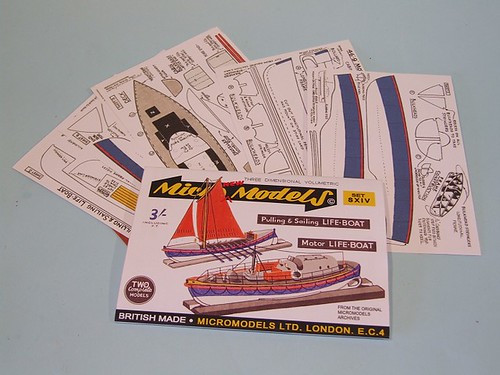

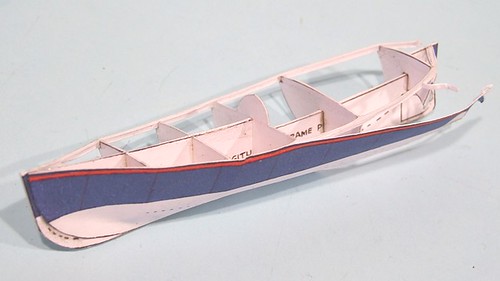

The principle of the kits is that the modeller buys the file along with the rights to produce as many copies for personal use as he or she wants. Production of the model is completely down to the purchaser. In this case that means you print off the kit parts yourself and lamitnate them on to cardboard to produce the components. In a couple of years if I want another kit, I just fire up the computer and printer to make it.

But can we go further ?

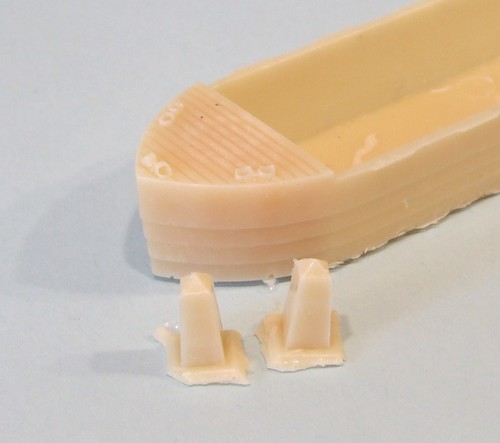

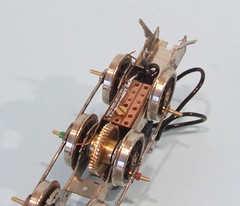

3D printing is much discussed on many modelling forums. At present the results aren't high enough quality for those of us in the smaller scales. Each layer of plastic laid down is arount 1/3rd of a millimetre high and to get acceptable results that has to be reduced by a factor of 10. On the other hand, people are experimenting like crazy with the technology:

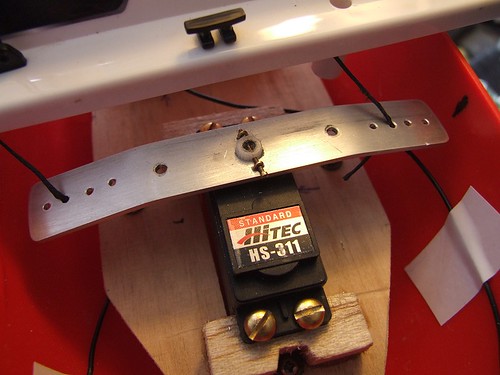

As you can see from the comparison above, the injection moulded model (Top) has nice smooth curves wheras the 3D printed version shows how the material is applied in layers. This will change though one day. The technology will improve, at which point will we all own our own printers and run off components ?

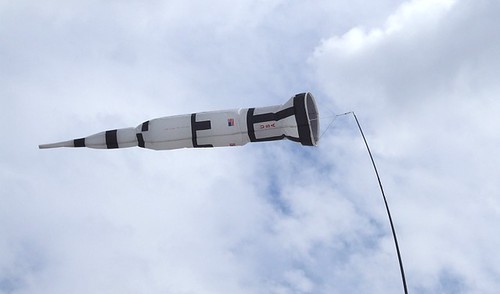

The machine at the top of the page is from Makerbot industries. It's a 3D printer you can buy off the shelf for around £1500 - less if you are prepared to do some of the assembly yourself. Obviously you then need to feed the machine a CAD file but it's a start.

Logically once you have the device then a Scalescenes style service where you buy the data for the part and run it off yourself is then a real possibility. The files themselves are readily available already and should you want the finished models then these can be bought on-line. Searching the Shapeways web site for the word "Train brings back 18 pages of results. I had a dig through and found a nice looking K6 phone box and a loco body that looks suspiciously like the one for the Hellingly Hospital Railway. Out of curiosity I've ordered these and will let you know how they turn out.

This is the future though. One day we won't store drawers full of components, we'll run them off as we need them. Except that we probably won't even do that, we'll buy in the data and make the model in CAD an then print it out. I'm not sure this sounds nearly as much fun but I suppose you can't stop progress.