With the mould ready, producing castings is easy. The recipe is simple, pour some hardener into a pot and then add the same amount of the contents of the other can. Be careful to get this something like right, or at least less harder than resin. The chemical reaction is exothermic - try and make it work too fast and the mix will heat up rapidly and bad things will happen. I'm not sure if you can make it catch fire but it's not an experiment I want to do.

With the mould ready, producing castings is easy. The recipe is simple, pour some hardener into a pot and then add the same amount of the contents of the other can. Be careful to get this something like right, or at least less harder than resin. The chemical reaction is exothermic - try and make it work too fast and the mix will heat up rapidly and bad things will happen. I'm not sure if you can make it catch fire but it's not an experiment I want to do.My cans came from Tirantis and according to the date on the side, are 5 years past their sell by. Undeterred, I had a go anyway. The hardener label instructs the user to give the liquid a shake before use, which I did on the second attempt. Both liquids were poured (not measured) into a plastic yogurt pot and stirred with a Tamiya stirrer.

The mix was then carefully poured into the mould. I sloshed it around to try and work out any air bubbles and left to cure. Attempt one took about 2 hours and the results were still a bit soft. On the next go, after shaking the hardener, things were much better with a good, hard, casting produced after 20 minutes.

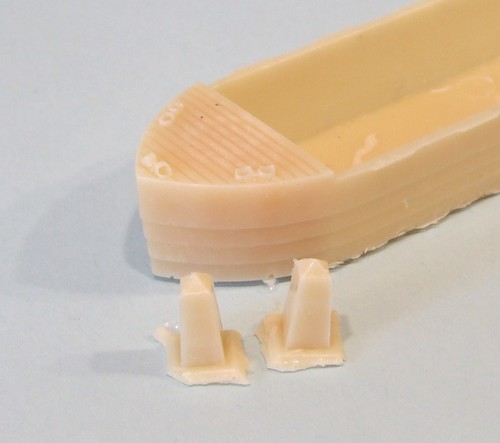

The mix was then carefully poured into the mould. I sloshed it around to try and work out any air bubbles and left to cure. Attempt one took about 2 hours and the results were still a bit soft. On the next go, after shaking the hardener, things were much better with a good, hard, casting produced after 20 minutes. Removing the casting from the mould takes a bit of flexing and probably would be a touch easier if some release agent had been involved but I don't have any to hand and it's not essential. The tiny details still have air bubbles in them which could be fixed with filler but probably won't be since these are wagon loads and will only be seen from a distance.

The important point is that this is all kitchen table work. No special tools are required, just 30 quid(ish) of mould material and casting resin. If you don't need the fine detail and want to make the resin go further than adding talcum powder will do the job but to be honest, it's probably not worth it. As a technique for mass-production of 3D objects, it's brilliant.

No comments:

Post a Comment