Do you consider yourself to be an engineer ? When you hear Kevin Webster in Coronation Street referred to as such, do you wince or shout at the telly ? If the answer is yes then look away now, and stop watching soap operas and get back to your shed and invent something.

Anyway, I am not an engineer but sometimes I have to pretend to be one. Today's problem is with my model yacht. It has two servos, one for steering and the other for tightening the sails. One is easy and done, the other is a new set of challenges.

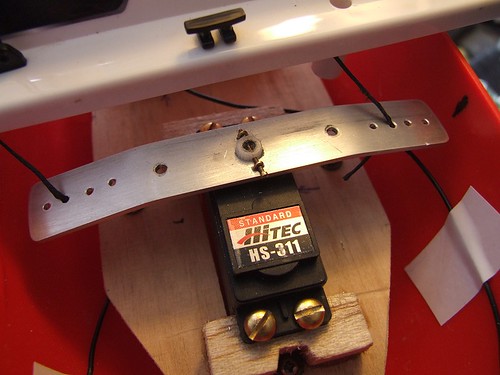

I acquired this model boat part converted from a RTR model. The last owner had ripped out all the old radio gear and installed a wooden tray to hold the servos. He'd also fitted an aluminium arm that when swung would pull on the cords attached to the booms the sails are fitted to. When the arm turned one way the booms would be hauled to the centre line of the boat, tightening the sails, turn the other and they can swing freely. Quite what this achieves is currently beyond me as I don't understand the principle of wind powered sailing, but that's what's supposed to happen.

Putting in the arm was the last thing done. Then the boat was put back together and returned to its box. And then passed on to me.

The problem seemed to be that the torque on the arm/servo union is going to be quite high. Normally, the arms are plastic and have splined holes to match the splined shaft of the servo. Here I have a metal arm with hole best described as "butchered" in it. Certainly not splined and hardly round. It was a reasonable tight fit but a bit of testing showed this wasn't enough to hold.

The servo shaft is nylon so glue wasn't an option. I'd probably fill the mechanism with gunge anyway. You can't solder to aluminium (well I can't) so I didn't fancy trying to make a collar with a grub screw and fit this. Finally, thanks to time and tea, I came up with the solution shown.

The arm is put in place, with the servo centred. A hole is drilled through the shaft and a tiny bolt screwed in. Then the arm is drilled to accept bent bits of brass. It's 0.7mm metal and the hole is the same so it's a very tight fit and required a little assistance from a toffee hammer. Finally a touch of superglue on these brass staples will hopefully hold it all together.

I'll let you know in a few days if this all works, and how my sailing lessons have gone. Or not if it all goes very badly.

(Note: The big news is I typed yacht several times in this post and spelt it correctly each time - a first !)

No comments:

Post a Comment