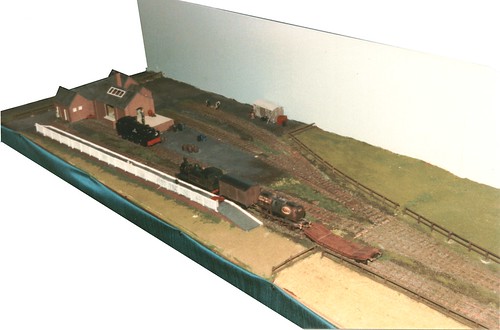

Happy with the running, it was time to do one of those jobs I hate in railway modelling - ballasting. It's boring, takes forever and if you don't get it right, can ruin the look of the layout.

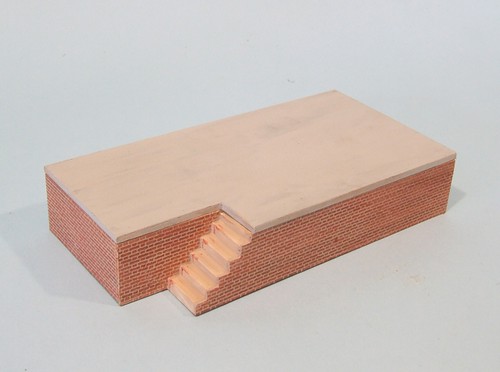

Happy with the running, it was time to do one of those jobs I hate in railway modelling - ballasting. It's boring, takes forever and if you don't get it right, can ruin the look of the layout.The ballast I used is a mix of granite and Slaters limestone left over from the Hellingly Hospital railway. The result is lighter than pure granite and I think is more appropriate for an estate railway. It's probably a bit coarse but the slightly cartoony effect appeals to me.

I like to trickle the stones down the centre of the track and bush it away from the rail sides and sleeper tops with a finger. Brushes tend, in my hands, to lift the stones up whereas number 1 digit pushes them down. Do a lot of it and you can certainly harden the skin on your fingers. Before this you exfoliate a bit, but then I'm worth it.

With the insides done I move on to the sides ad do the same thing on the edges. It's important to keep the ballast line neat and reasonably straight. On the mainline this would be managed by the plate layers and they would be in competition with other gangs for neatness. On an estate these matters are a lot more relaxed but even so, the lord of the manor will want things kept tidy.

Glue is the normal 50/50 mix of water and PVA with a couple of drops of washing up liquid. Dripped on with a pipette, the thing I discovered was that doing this AND taking a photo is harder than it looks !